|

|

Post by b4nj0 on Feb 12, 2020 18:07:31 GMT -5

Ah! the LeClanche cell. We'll be back on "jars' soon!

What about a <protected> 18650 cell? (preferably in a dedicated holder?) Such a contraption ought to fit into a bathtub rout Leo-type? Maybe a charge facility could then be arranged by changing the guitar jack socket to a TRS? Mmm- I'd have to think about that one... perhaps not- more (failsafe) switching required?

The 18650 is very familiar to vapers but is ubiquitous in laptop battery packs and no doubt elsewhere too. A Tesla has about 7,000 of the blighters. Massive bill when they need replacing due to fast charging ... Because in this case it's a single cell you don't need to ensure cell balance. Absolutely avoid cheap chargers and cheap cells (even protected ones). That's a mugs game. Those cell 'phone flat packs? They have an alarming tendency to swell and that is indeed a clarion call to senses.

I wouldn't put batteries or cells in guitars at all, for me it's an oxymoron, but then again I'm not a bass player!

e&oe ...

|

|

|

|

Post by ourclarioncall on Feb 12, 2020 18:47:48 GMT -5

|

|

|

|

Post by newey on Feb 12, 2020 22:38:04 GMT -5

As for onboard rechargeable power, how about an old laptop battery? This could probably go into a Strat trem cavity if the vibrato were removed and the guitar converted to a hardtail. You could just use the laptop's charging brick, wire a female battery plug to accept the male from the charger, wire the plug to the battery, and either mount the small plug to the trem cover, or just have the plug hang from the wire and store it under the cover until needed.

|

|

|

|

Post by sumgai on Feb 12, 2020 23:22:24 GMT -5

I wouldn't put batteries or cells in guitars at all, for me it's an oxy moron, but then again I'm not a bass player! I highlighted the first things that are going to get c1's attention.... might get a bit interesting in here, after two full pages of tech stuff.... |

|

|

|

Post by sumgai on Feb 12, 2020 23:47:32 GMT -5

Hmmmm, 16 hour battery life , sounds a bit more appealing. It would appear that Shure is starting to think out loud again, like they did in the 50s and 60s when they were generally considered to be top-notch players in the game. But for me, and I'm sure for most folks, battery life is pretty far down the priority list. First and foremost would be clarity of tone - who needs a battery that lasts forever when the tone is crappy? (That would be due to a bad signal path along the radio transmission path... further due most likely to an underpowered transmitter.) Then I'd want reliability, and after that, price might enter into my considerations. At that point, battery life is not an issue. If I have to replace it "more often" than the next guitarist, how am I harmed? (Other than cost, if I don't use rechargables.) The obvious answer is: I'm not. If my fingers can be made to work at picking and fretting strings, then they can also be made to change batteries, no sweat. I'm gonna put on my Bad Cop hat here, and let it all hang out - if one is too lazy to change batteries when needful, then perhaps he/she should give up this idea, and stick with cables. Also up for grabs (my Good Cop hat is back on), the 18650 is found in probably 95% of all major brand power tool battery packs. The cheap packs may use something inferior (YouTube has plenty of videos on how to replace them), but the expensive, brand-name packs come with the good stuff right out of the box. This makes finding them for sale a walk in the park. And on another side note, I've heard of only one instance, ever, where a battery installed inside of an acoustic (with a piezo and amp) made like Smokey the Bear's nightmare. Further inspection revealed that the circuit board had a low-resistance, not-quite-dead-short across the battery. That's a factory defect, not a natural consequence of having a battery built into one's guitar. Hell, I've got coin-shaped miniature cells (batteries) in my hearing aids, right next to my skull - do I look worried?  Final note: Insurance companies don't ask if your valuable, insurable guitar has a battery inside of it - they figure the risk factor is too small to fuss over. HTH sumgai |

|

|

|

Post by b4nj0 on Feb 13, 2020 9:51:48 GMT -5

I anticipated that SG which is why I deployed the caveat that I don't play bass. I have a Gretsch Committee bass Mk 1 hanging on the wall here. I've always harboured a sneaking desire for a fretless Jazz bass too, but Fred's creation sure is pretty to look at ... I know it's unwise to generalise, but bass players are much more open to change than significant numbers of guitar players, and that extends to include profiles as well as an attitude to on board electrickery. There's nothing wrong with that- each to his own etc.

I can see why active electronics in order to make the bass have more impact in a band environment is appealing and rightly so, but I haven't noticed guitar players really <needing> to follow suit. Using active solutions helps to expand the envelope and provide new options which is healthy, but (and I'm far from representative) I just don't feel that need. That said, I'm reasonably sure I'm not in a minority. Not "right" especially, just "nothing to pique my interest here- move along now". We're a broad church- especially we Nutz, and that's how it is.

The first guitar I screwed together was an Esquire inspired by images in Ken Achard's green book about the Fender guitar. I had someone wire it back in those days and took the option of having a treble booster they were promoting installed (in an Esquire???) I very soon had that removed free of charge by letting them have the booster back. This kind of prejudiced me against such additions to vanilla guitar circuitry. Now I think about it, I am struggling to bring to mind any examples of active circuitry in the instruments of those pioneers that so influenced me, I'm sure there must be some but I cannot remember any.

As far as lithium cells go- I'll just think about what the French ATC christened "The Boeing Barbecue" for a moment. The FAA have strict limits in the size of Lithium.power sources that are allowed on airplanes, and they are far from alone in jurisdictions in that thinking. 18650 LiFePo4 cells (such as those in the Tesla) are much less risky, especially if using "protected" examples, but I keep all my lithium derived packs and cells (of whatever chemistry) at storage charge in "fireproof" bags inside an ex-issue ammunition box. It's just a healthy respect for the power density of these batteries and an understanding that once they go- they don't need oxygen to sustain the burn. Excepting "smart" 'phones and laptops and the like which always come with suitable balancing and / or safety provisions, I don't leave any charging (or discharging) lithium unattended.

e&oe ...

|

|

|

|

Post by ourclarioncall on Jul 23, 2020 20:24:18 GMT -5

neweygot an pics of this bus thingy? “I have used a buss fashioned from a strip of metal to avoid that problem, on the last couple of projects I did. It's screwed into the side of the cavity at each end and when the sldering is done, a strip of electrical tape keeps it isolated from any hot leads after everything is reassembled” so you shield everything with copper foil, then attach the bus thing and then what? Solder every ground wire to the bus? If so how do you ground the copper cage ? I’m guessing the bus is connected to the cage and the ground/return wire connected to the output jack connects to the bus? also what about the bridge ground , going to the bus too ? why is it called a bus ? Coz a bus is one universal organised unified place where all the ground wire passengers get on board and travel to the same destination ? why do I ask so many questions lol 😆

|

|

|

|

Post by ourclarioncall on Jul 24, 2020 5:22:53 GMT -5

Carbon conductive paint

Watching a guy paint his guitar with this stuff on YouTube and in the comments section one comment was that the company claimed 34-55ohms resistance which is not ideal as you are aiming for 0 ohms ?

Another comment said that he tried the paint and had 300 ohms resistance

|

|

|

|

Post by ourclarioncall on Jul 24, 2020 5:23:31 GMT -5

Frets mentioned painting carbon paint first and then applying copper tape on top

What would be the advantage of this ? More layers , stronger more effective cage ? A backup in case the copper gets ripped or damaged and doesn’t work properly ? In the case of non conductive copper tape where lots of solder is needed the solder might get damaged or deteriorate and the paint underneath will step in ?

|

|

|

|

Post by ourclarioncall on Jul 24, 2020 5:24:51 GMT -5

Pickup Screws touching faraday cage

Thoughts on this ?

—

paraphrased YouTube comments

“Pickup screws cannot touch the faraday cage”

“A lot of weird things happen with your output if they do”

“A very very small non conductive perimeter around the pickup screw holes Is necessary “

|

|

|

|

Post by b4nj0 on Jul 24, 2020 6:16:21 GMT -5

Does that mean mounting screws or the slug screws? Provided the mounting screws show no continuity with the pickup's windings I can't see a problem, indeed if the pickguard is screened then it's almost a given, but if the slug screws make contact then there may well be an issue.

e&oe ...

|

|

|

|

Post by newey on Jul 24, 2020 8:25:48 GMT -5

neweygot an pics of this bus thingy? "Bus" is just shorthand for the term "bus bar", as far as I know the usage has nothing to do with vehicular buses. To show a pic, I would have to destring and remove the pickguard from a guitar. I think my verbal description should suffice. All grounds are connected to it, including the bridge/string ground and the output jack ground. It grounds to the shielding by physical contact. As for the mounting screws causing a problem, I've never heard of that. b4njo questioned whether the reference was to the coil screws or to the mounting screws (which would not be electrically connected to the coils), but the statement that "A very very small non conductive perimeter around the pickup screw holes Is necessary“ would seem to indicate it's the mounting screws which are referenced. If the coil screws were a problem, that could be easily solved with a strip of electrical tape across the underside of the pickup. And I can't see where contact with the foil by the mounting screws would be an issue. After all, the strings/bridge should be electrically continuous with the shielding, so what difference would/could the pickup mounting screws make if they were likewise so connected? |

|

|

|

Post by reTrEaD on Jul 24, 2020 12:58:46 GMT -5

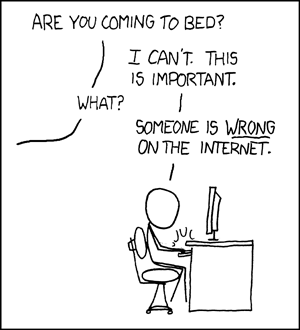

Pickup Screws touching faraday cage Thoughts on this ? I can't imagine why this would be a problem. Whether we're talking about the screws which function as pole-pieces or the mounting screws, they both attach to the baseplate. The baseplate is generally connected to a braided shield for the pickup cable, which ultimately is connected to the sleeve of the output jack. And the 'faraday cage', copper shielding, or whatever else is used to shield the cavity is also ultimately connected to the sleeve of the output jack. paraphrased YouTube comments “Pickup screws cannot touch the faraday cage” “A lot of weird things happen with your output if they do” “A very very small non conductive perimeter around the pickup screw holes Is necessary “ There are tons of incorrect statements being made on youtube and other places on the internet. Don't allow this cause you to lose any sleep.  |

|

|

|

Post by ourclarioncall on Jul 26, 2020 20:50:14 GMT -5

Does that mean mounting screws or the slug screws? Provided the mounting screws show no continuity with the pickup's windings I can't see a problem, indeed if the pickguard is screened then it's almost a given, but if the slug screws make contact then there may well be an issue. e&oe ...Yeah , doesn’t make any sense does it Ya just don’t expect someone say something Like that with such conviction and sounding seemingly knowledge on the topic and be so wrong. 🤔 hmm. Oh well. One less shielding pitfall to worry about reTrEaDsleep ?! I have 5 kids 😁 those days are gone lol. Saying that, my youngest is 1 now and I am actually getting much more shuteye, but i am guilty of not taking the opportunity to recharge my battery as I’m discovering golden threads on GN2 from a decade ago ☺️ |

|

|

|

Post by ourclarioncall on Jul 26, 2020 20:56:17 GMT -5

neweycould..... you attach all the ground onto the copper shielding tape , instead of having the bus ? I assume you could but the bus is a better cleaner easier place to attach to ?

|

|

|

|

Post by newey on Jul 27, 2020 6:06:12 GMT -5

could..... you attach all the ground onto the copper shielding tape , instead of having the bus ? I assume you could but the bus is a better cleaner easier place to attach to ? You could do so, but many here (following the lead of ChrisK) will tell you not to rely on your shielding to carry signal. You want the shielding and the signal grounds separate right up until the point where both are connected to the output jack sleeve. This is not really an electrical matter, but more a matter of reliability- the shielding should not be relied upon as a ground, run a wire instead. |

|

|

|

Post by ourclarioncall on Jul 27, 2020 8:12:42 GMT -5

could..... you attach all the ground onto the copper shielding tape , instead of having the bus ? I assume you could but the bus is a better cleaner easier place to attach to ? You could do so, but many here (following the lead of ChrisK) will tell you not to rely on your shielding to carry signal. You want the shielding and the signal grounds separate right up until the point where both are connected to the output jack sleeve. This is not really an electrical matter, but more a matter of reliability- the shielding should not be relied upon as a ground, run a wire instead. Thanks newey, Makes a lot of sense . so just to clarify.... Do you need to attach the copper shielding tape to the output jack with a wire? Or is it already connected to the output jack because it’s connected to the bus - and the bus has a wire connected to the output jack ? Another question , what rough dimensions and material is the bus? Do you screw it into the wood with a screw at each end? Is the bus laying flat on the bottom of the cavity or on the side wall area? If the side then i guess it would be bent to match the curve ? Love the idea, I basically want to copy what you’ve done or pretty similar. My plan is to try the main two things I’ve read about which is to shield the cavity and pickguard with conductive copper tape , put in one of your bus thingys and wrap copper Tape round the pickups on top of frets suggested “pickup tape”. I won’t bother shielding the input jack cavity or worry about the short run of wire |

|

|

|

Post by newey on Jul 27, 2020 12:28:57 GMT -5

Or is it already connected to the output jack because it’s connected to the bus - and the bus has a wire connected to the output jack ? Yes. The bus is screwed into the side of the control cavity, thereby physically contacting the shielding. I have used a paperclip, shaped like "]", and I use a needle-nosed pliers to fashion loops at both ends to run a screw through so as to screw it in. The purpose of the bus is just that it's too hard to solder all the grounds to a washer. After I'm done, a strip of electrical tape over the top of the bus prevents any inadvertent contact with other components once the pickguard is reinstalled. The bus just sits a mm or so off of the side of the cavity, although it really doesn't matter if it contacts the side. I cut the clip to size, about 2 inches long not including the bending for the screws. I don't know about frets' reference to pickup tape, but wrapping your pickup coils in copper tape (people here have experimented with this) is likely to adversely affect your tone. I would say just shield it and see how the noise level is first. |

|

|

|

Post by ourclarioncall on Jul 27, 2020 12:54:07 GMT -5

neweyDo you have a bus for your signal/hot wire ? Or do you just run it through the cavity from your output jack to your volume pot ?(I assume it’s a strat type guitar) On the shielding , what about this version ? www.premierguitar.com/articles/26279-mod-garage-how-to-shield-single-coil-pickups?page=2It’s supposed to retain the high end by leaving a small gap in the copper tape/wrap. I think the tape frets is referring to is some sort of tape that goes over the coil of wire itself complete covering it and then you put the copper tape on top . I have a set of cheap bar magnet pickups with this tape stuff wrapped around the coil. So it would be an easy experiment to wrap a bit of tin foil or copper taperound the pickup and connect to the ground wire to see for my self if it has any benefit or not .

|

|

|

|

Post by frets on Jul 27, 2020 14:59:55 GMT -5

You got the wrong girl, I never would wrap pickups in copper tape. That wasn’t me. I never put copper tape on the backs of pickups. I shield all the cavities I work with in copper tape - each cavity of the guitar gets coppered and I solder a continuous ground wire from each coppered cavity to each other cavity and culminating in the continuous ground soldered to the back of a pot. 😇 Weeeee !!!

|

|

|

|

Post by ourclarioncall on Jul 27, 2020 20:15:24 GMT -5

You got the wrong girl, I never would wrap pickups in copper tape. That wasn’t me. I never put copper tape on the backs of pickups. I shield all the cavities I work with in copper tape - each cavity of the guitar gets coppered and I solder a continuous ground wire from each coppered cavity to each other cavity and culminating in the continuous ground soldered to the back of a pot. 😇 Weeeee !!! Ah apologies. I think you told me about the “pickup tape” and how to apply it and a warning not to stick the copper tape directly onto the coil itself . i probably made it sound like this was something you do yourself . so do you think there is no benefit to shielding the cavity AND shielding the pickups ? I’m intrigued to try both , maybe one at a time , then both together to see if it makes any difference. Possibly crank my amp up , volume and gain , to get as much hiss and hum as possible to make any improvements obvious |

|

|

|

Post by frets on Jul 27, 2020 21:21:45 GMT -5

Clarion,

I am a proponent for shielding and grounding the cavities, but not the pickups.

|

|

|

|

Post by newey on Jul 28, 2020 5:54:15 GMT -5

Do you have a bus for your signal/hot wire ? Or do you just run it through the cavity from your output jack to your volume pot ?(I assume it’s a strat type guitar) The bus is a substitute for star-grounding to a washer. The "hot" line is run as you describe, to the volume pot. By all means, experiment with wrapping the coils if you want to experiment. There are a few threads here that discuss that, and one experimenter did suggest that leaving a gap would minimize any tonal effects. But of course that was just subjective, YMMV. |

|

|

|

Post by ourclarioncall on Jul 28, 2020 9:43:55 GMT -5

neweyi just tried using a couple of washers actually as a star ground . Well , I had 2, one for signal Hot and return ground. They were sort of floating . I never tried soldering , I just wrapped the wire tight around the washers then put a bit of masking tape on top. I thought about doing something like this making a sandwich 🥪 - two pieces of metal with screw holes at both sides For the bread and the ground wires are the filling. Drew the sandwich together against the cavity wall or floor. Might be better if one of the metal strips was permanently attached and then the other can be loosened off to insert or remove the ground wires . No need for solder.

|

|

|

|

Post by ourclarioncall on Jul 28, 2020 9:53:42 GMT -5

Better drawing. So metal strip 1 is screwed in with narrower screws and never moves, but strip 2 is screwed in and out of the wider holes to open and close the sandwich. the metal strips really wouldn’t have to be very big either eh? As you only need to hold a few wires. 2 or 3 inches would do . I just took a look at the hinge on my living room door, maybe something like a small hinge could work and it already has plenty holes drilled in it, plus the pieces are nicely connected. 🤔 hmm, maybe il take a trip up to the hardware store and see what they’ve got  |

|

|

|

Post by newey on Jul 28, 2020 10:27:37 GMT -5

I would not trust not soldering the connections.

|

|

|

|

Post by ourclarioncall on Jul 28, 2020 10:36:26 GMT -5

Ah, ok, best to have them permanently fixed than squished ?

i just found something that might work , it’s called fixing plate or mending placte . Just a 2-3 inch wide strip of steel with 4 countersunk holes. Couple of mm thick. It looks just like my drawing actually

This could work well for my sandwich or “solder sandwich” 🙂

what about the whole mixing of metals ? Mild or stainless steel on top of copper tape cause a problem? I think I read it was zinc plated ?? I’m clueless

p.s so what was this issue with the washers? I think you say difficult to solder to ? Difficult or awkward ? What about soldering to something in my pic?

i think I would prefer to have the metal strip flat on the cavity floor so there is less stress on the wire as it would be laying flat on the cavity floor and straight into the sandwich . I have had problems with wires breaking as I have lifted and closed the pickguard so many times recently , with twisting and pulling etc, but under normal circumstances you would just “set it and forget it” . Also I won’t have to bend or shape it to the cavity wall. Saying that , I have tons of room in my cavity as I routed it all out, others may be tight for space

|

|

|

|

Post by newey on Jul 28, 2020 10:52:28 GMT -5

The "mixing of metals" issue might be a longer-term problem, I've never encountered any issues with that. The issue with washers was just the amount of room on the washer, if it was small enough to fit the cavity wall, there wasn't a lot of room to solder to it. I "rough up" the finish of either washers or paperclips with a file or sandpaper before using them to solder onto.

I've never used the bottom of the cavity, I would worry about using too long a screw and having it protrude out the back of the cavity. The side wall works fine, plenty of depth for the screws and it keeps things out of the way o other components.

Over the years, I have used the washer method a lot more often than making a bus. The bus was just helpful on a couple of guitars where I had quite a few grounds to deal with, for example, on my 4-pickup Strat clone.

|

|

|

|

Post by ourclarioncall on Jul 28, 2020 11:07:36 GMT -5

The "mixing of metals" issue might be a longer-term problem, I've never encountered any issues with that. The issue with washers was just the amount of room on the washer, if it was small enough to fit the cavity wall, there wasn't a lot of room to solder to it. I "rough up" the finish of either washers or paperclips with a file or sandpaper before using them to solder onto. I've never used the bottom of the cavity, I would worry about using too long a screw and having it protrude out the back of the cavity. The side wall works fine, plenty of depth for the screws and it keeps things out of the way o other components. Over the years, I have used the washer method a lot more often than making a bus. The bus was just helpful on a couple of guitars where I had quite a few grounds to deal with, for example, on my 4-pickup Strat clone. Maybe something along these lines could work www.amazon.co.uk/SHIEM-square-copper-connector-terminal/dp/B07FF6N473I thought about cutting the plastic off of a piece of connector block (chop block) . Not sure if it’s made of copper or brass tho . And I suppose it’s still a bit bulky Yeah, one of my circuits had so many ground wires you would have thought there was guy with dreadlocks sleeping rough under the pickguard 😊 |

|

|

|

Post by ourclarioncall on Jul 28, 2020 11:38:22 GMT -5

Alright, il have a think bout it.

You can get pieces of copper strip about 1mm thick x 10mm wide x 6 inch long . No holes in it tho so would have to drill.

The steel strip with pre drilled holes seems good enough

It’s been said the copper tape deteriorates over time anyway.

Thanks again Newey for playing ping pong and answering all my questions 😎

|

|