|

|

Post by newey on Feb 21, 2010 0:02:59 GMT -5

For some time, I've been considering building a wooden "stompbox", like Seasick Steve's "Mississippi Drum Machine":

Just got to find an appropriate wooden box.

I thought to use a piezo, but would that mean a preamp/buffer (and a lot more complexity than this merits)? This should be a passive deal if possible. Could I use a piezo passively in this type of application?

What about that PVDF film stuff?

And perhaps vol. and tone controls? Would there even be a point to having a tone control?

Anyone's thoughts on this appreciated, I'd like to not end up "buying and trying" a bunch of different mics before finding something that works OK.

|

|

|

|

Post by ashcatlt on Feb 21, 2010 0:54:54 GMT -5

Some links to commercial versions of what you're talking about: Stomp boxan electric tap shoe, not quite what you're talking about, but almost interesting. The answer to your question kind of depends on what you're looking to connect it to, and what kind of tone you hope to achieve. You need a transducer of some sort, and it needs to be be amplified somewhere along the line. The piezo element itself is passive. It will require amplification at some point (which will necessarily be an active stage), and may want some buffering before it reaches that stage (depending on what that stage wants to see). FWIW, there is a whole realm of noise "artists" who are perfectly content to connect a piezo element (generally ripped out of a cheap RS buzzer) directly to a mixer or amplifier input without any intervening electronics. I can't imagine we'd be looking for any kind of hi-fi response out of this stomp object, would we? |

|

|

|

Post by newey on Feb 21, 2010 1:07:15 GMT -5

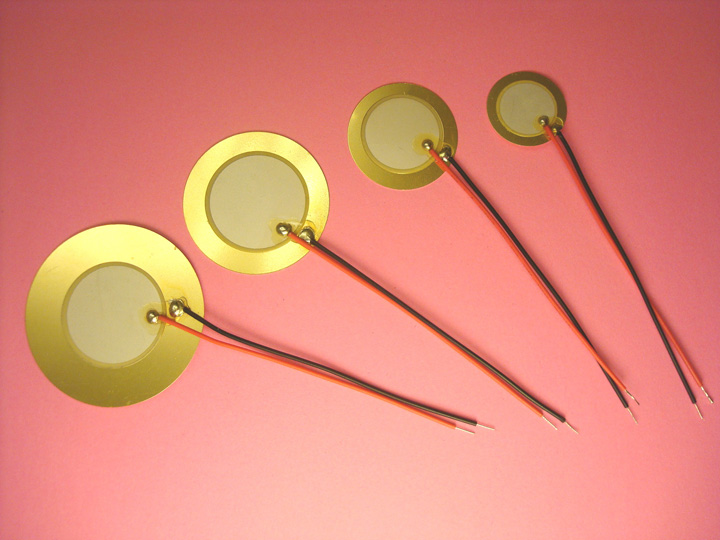

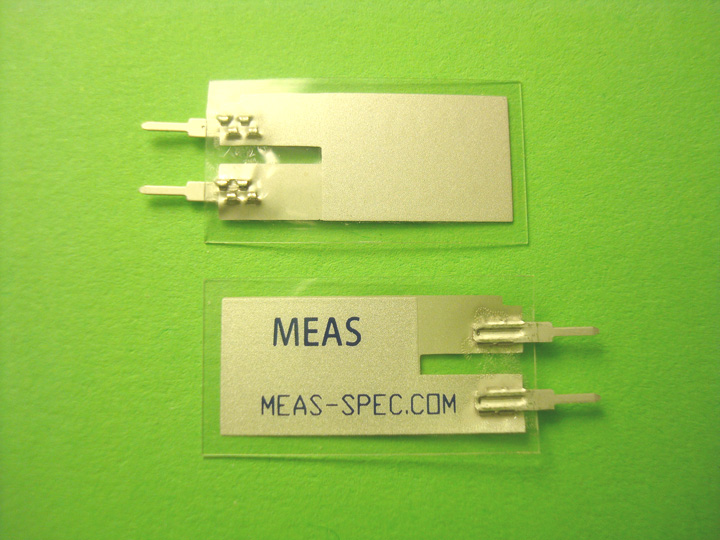

No Hi-Fi at all, in fact low fi is probably better . . . I sort of jumped the gun, and just bought a few piezo elements for experimentation, both with this in mind, and for possibly adding a piezo to one or more guitars. Bought a pair of these, in the 35mm size:  And a pair of these:  Would there be value in using 2 elements, maybe one of each of these, at different locations in the box? BTW, the "stomp shoe®" is a good idea, but it needs to be wireless! Maybe hollow out the heels to hold a wireless transmitter . . .  |

|

|

|

Post by newey on Mar 12, 2010 21:52:19 GMT -5

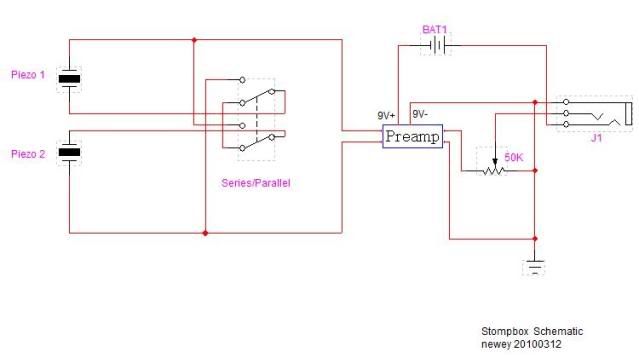

Still looking for an appropriate wooden box. Meanwhile, I drew up a wiring scheme as a trial balloon. And came up with a few questions: 1) Can 2 piezo pickups be wired in series? Is there any point to so doing? 2) Have I got the battery disconnect, using the jack ring connection, wired right? Not sure if this is getting an active preamp or not, but I drew it up that way, figuring that if I did put 2 in series the resistance would be huge and a buffer of some type would be needed. 3) Is the whole thing just GeFooey©?  I'm tempted to use one of each type of piezo I've got, mounted on different surfaces of the box, to get a variation in sounds. The PVDF ones have a very wide frequency response, well above and below human hearing, and consequently need to be shielded. The mfr recommends using copper tape with conductive adhesive- and I just happen to have a roll of that lying around, go figure.  Version 2.0 would be to wire it for stereo with 2 piezos, hoping to get a slight lag between the channels, to get a sort of echo/depth to the sound. |

|

|

|

Post by ashcatlt on Mar 12, 2010 22:14:22 GMT -5

1) Don't know, but it looks to me like both pickups are shorted in the position you've shown the switch. I presume you intended this to be the parallel position. What you've got now is Off/Series.

2) Looks like you've got the same problem here that you had with your stereo tele diagram. I think I know what you meant to draw, and that would work, but it don't look right as is. You want the battery connected to the ring of the jack, which is closer to the sleeve (further to the right in the above diagram) than the tip.

3) I think it's a good idea, but I'm not sure how much practical satisfaction you're going to get from two transducers. Unless we can talk to somebody who's actually done it, you'll just have to wire it up to be sure.

|

|

|

|

Post by JohnH on Mar 12, 2010 23:18:07 GMT -5

I think this is a great project, and Seasick Steve is a cool old codger.

I agree with ash on the series parallel. In parallel mode, you need to swap the pickups that connect to hot and ground.

The difference series/parallelwill be around 6db of volume, and maybe a change in tone. If you set an input impedance that is low enough to roll off a bit of bass in series mode, then in parallel mode you will get relatively more bass but less overall volume. This is different to guitar pickups, because we are talking of capacitive pickups rather than inductive ones, so loading tends to cut bass rather than treble.

I think the blending of different parts of the box is another interesting aspect - more resonance near the centre of a panel than the corner. and there's phasing to experiment with.

I think it could be that after some testing, one or two configurations are found better than others, so I'd suggest keeping it a a test set up until you are ready to do a final build

cheers

John

|

|

|

|

Post by newey on Mar 12, 2010 23:33:55 GMT -5

OK, back to the drawing board.

Yes, experimentation is in order. I want to get a nice deep "thump" out of a not-too-big box.

If I were to run this without a preamp, a la Ash's noise artists, do I need to worry about the input impedance at the amp?

The closest I can come on a cheap box about the right size is one of those wooden boxes to hold a single wine bottle, with a slide-out top. The top would become the bottom, and provide access to the innards. It also might sound better with an open bottom, minus the lid, so that's another variable to try.

|

|

|

|

Post by JohnH on Mar 13, 2010 0:19:28 GMT -5

What I found with the larger flat piezo discs is that they can indeed drive a reasonably not too high impedance. The one in my guitar is about 20mm diameter, and I loaded it with 150k to control a booming sub-bass.

For testing, these should be fine into a guitar amp input, or via a switched off, non-true-bypass stomp box of any kind (eg anything by Boss), into a line input on a mixer. It will then come down to whether there is enough volume, but I think that is a good place to start, then determine a preamp or EQ to suit if needed.

cheers

John

|

|

|

|

Post by gumbo on Mar 13, 2010 7:21:38 GMT -5

...or just grab yerself an old Roland drum brain (TD-3??), hook up the piezo output to one (or as many as you like) of the six-or-so sensor inputs...select your favourite "thump", and output to a mixer channel.... ...don't ask me how I know this works....  |

|

|

|

Post by newey on Mar 13, 2010 23:28:04 GMT -5

There's a ton of "how-to" stuff out there on the web. Lots of guys using cigar boxes, like this guy:

I have yet to read much of anything on the electronics end, though. Most of these are just run straight to a jack, no controls whatsoever. So, I will have to experiment at bit.

Several folks mentioned covering it with carpet on top, supposed to give more of a bass drum sound. One guy used a surplus drum trigger.

The lid of the cigar box was mentioned as a rattle source by several people, so perhaps removing the top is the way to go. I think I want something a bit bigger than a cigar box, though.

|

|

|

|

Post by newey on Mar 14, 2010 0:28:12 GMT -5

Here's the revised schematic, hopefully solving the problems previously identified . . .  EDIT: EDIT: Just noticed the loss of clarity in the above revised image as compared to the first one. Realized I forgot to save it as a .gif file, so it defaults to save as a .jpg file. Moral of the story, use .gif for diagrams! |

|

|

|

Post by sumgai on Mar 14, 2010 12:19:00 GMT -5

newey, So, you don't save each diagram in native format? You could just go back and re-save it as a gif, and then post that instead (by editing your link to change the extension, obviously).  BTW, I looked at several of the other "related" videos, did you happen to see this one about "overthinking" the whole idea? sumgai |

|

|

|

Post by newey on Mar 14, 2010 13:57:22 GMT -5

Yeah, I saw that one, too. But hey, last time I checked, this was still GuitarNutz2!

|

|

|

|

Post by ashcatlt on Mar 15, 2010 0:00:26 GMT -5

I looked at your new diagram earlier (before noon, you know...) and it looked much better.

newey, I'm really into your experiment here, and don't want to dissuade you, but I know a couple people for whom stomping is an important part of their performance. When I see them perform, they are usually stomping on a relatively resonant plywood stage within about 1' of the nearest "live" mike stand. We never have any trouble hearing the stomp!

In the direction of gumbo's post - it'll probably work just about as well for a drum trigger whether it sounds good on its own or not.

|

|

|

|

Post by newey on Mar 15, 2010 5:29:13 GMT -5

My practice area, however, is plush-pile carpeted. And the wife already nixed the idea of building a plywood stage over it!   I decided the cigar box was worth a try, since I wasn't finding much else around. I ordered one from Kmart online, of all places, for $6. So hopefully in the next few weeks, I'll have some hands-on data to post. I'll do a test run with just one piezo at first, temporarily mounted, in a passive configuration, and decide from there whether to incorporate more features or not. Any construction calls for drilling a hole, at the very least, for an output jack, so I'll mount that first, and jury-rig from there. Of course, the piezo, even for testing, must be solidly mounted. I note that several of these how-tos use a piece of wood to "sandwich" the piezo to the box, rather than simply taping them down. Several folks mentioned using these with various guitar pedals to good effect, which of course would buffer the output as well, if not "true bypass" types. This has me thinking that perhaps the electronics should be outboard, rather than in the box. Putting a 9V battery and circuitry inside the box itself might cause rattling or other diminution of the sound, and the circuit board might vibrate something loose over time. We'll see how things go. |

|

|

|

Post by JohnH on Mar 15, 2010 6:41:12 GMT -5

newey - you definately have a few of us interested in this one! Good project.

I was wondering how the sounds might vary between a transducer on the top that you hit, as against one on the side or underneath which might have less slap and more boom. You could have a knob to mix them if there is mileage in that (got a circuit ready...)

The step by step approach will reveal much however.

John

|

|

|

|

Post by newey on Mar 23, 2010 20:43:18 GMT -5

So, I got the wooden cigar boxes (I ordered 2 so I'd have a backup in case I screwed the pooch building it!). These were $6.99 USD from Kmart.com, plus S & H. They look like this. They have a light lacquered finish on 'em.    The boxes are somewhat flimsier than I envisioned. I may need to run some stringers across the inside to stiffen it up, which will affect the tone, certainly, but perhaps beneficially. I also need to get a jack with a deep barrel, as a standard one doesn't protrude enough to take a nut. So, this is just jury-rigged for testing at this point anyway. I started out with a 250K pan (NOT "Blend"!) pot. I have several of these, buying them after being assured they were the real deal. And it fit through the wood OK. I have only one-half of the pot wired for now, as initial testing is just using a single piezo element- the disc-type. The Polyfilm piezo will have to wait- I need some really small gauge wire to put leads on it, and it requires shielding. But the pan pot allows me to add another pickup of either type for future experimentation. The knob says "Tone" on it because I had one laying around, but not a Vol one. And, for now, the jack is just stuck into the hole. Looks like this:  In initial testing, I have the piezo disc taped to the underside of the top of the box. I used long strips of paper nurse's tape, as neither plastic electrical tape or painter's tape would hold it down well enough. Hey, it works! But the sound was not what I was hoping for right out of the box (so to speak). It's rather trebly, not so much a "Thump" as a "Thweeek". It's usable, but not ideal. And, it's somewhat noisy at idle. I tested it through my EH .22 Caliber amp, into a Peavey 2X10" PA cab. I had to keep the volume down to about 3-4 to have it be quiet, and the stomp thereabouts is at a good practice level, but adding any more gain produced more noise than one would want. I'll have to try it through a different amp, with a different cable, to be assured it's the box itself. If it is, I may have a faulty ground somewhere in there. If all else fails, shielding the box may be in order, but more testing is in order first. For the second test, I tried dampening the box out by the simple expedient of inserting a pair of rolled up gym socks in the box. These were tall enough so as to contact both the top and bottom of the box fairly tightly when the box was closed. This was a definite inprovement- it took away a bit of the ringing tone of the thing, but it's still far from a "thump". With the socks, it had the sound of someone tapping his or her foot on a wooden floor. If more volume were available without noise, this would be a usable sound, like tapping a foot on a stage. The next steps will be to move the pickup to the bottom, and try it with a piece of carpet on top of the box. I also haven't tried it with any pedals, which are reputed to be helpful with these things. Gotta nail the clean sound first, deal with the acoustics of the thing, then get into things electrical. Much to do, many options to try . . .  |

|

|

|

Post by newey on Mar 24, 2010 19:52:57 GMT -5

OK, Round 2 of testing:

After verifying what I heard with and without the socks yesterday, I moved the piezo to the bottom of the box (w/o sox). I detected no real difference in doing so. Adding the socks had the same effect as with the piezo on top- better, not great.

However, moving the socks so they directed compressed the piezo element sounded better- a bassier sound, but pretty well damped out.

I then tried it into my Fender (after swapping cables into the EH, no difference). This cured the noise issue, I can crank the volume without noise on the Fender. Hmmm. The EH "stompbox" amp isn't the quietest thing in the world, but it's not obnoxiously noisy with a guitar , so I don't know why I'm getting so much noise with the box plugged into the EH.

Problem is, the Fender is my main guitar amp. I'll have to try the bass amp with it as well; if that's quiet, then I can use that for the box and plug the axe into the Fender.

Clicking the gain switch on the Fender, however, produced ear-splitting feedback (of the "mic-facing-the-PA-speaker type, not the Hendrix type!). And the reverb resulted in a "tank-kicker" sound with lots of spring rattle.

For the next test, I decided to see the extent to which the lid might be rattling, contributing to the sound. So I taped over the lid, sealing the box closed. This helped a lot, getting a lot closer to the drum thump I'm looking for. But keeping the box taped up is pretty impractical.

But I determined that the top rattling was a big part of the problem. The next step was to dampen out the top entirely, as it would be with a piece of carpet. I used a folded up dishtowel, as I didn't have any small scraps of carpet handy.

This seemed to produce the best results, the most bass drum-like sound. Although no one is going to confuse this with a bass drum, I was definitely closer to a Thump with the top damped. Even moreso with the socks reinserted. It requires a good deal of volume, though, as the box is basically fairly muffled sounding.

Next, I'll try putting some carpet on the inside of the top, see if I can get the sound without covering the top in carpet. I'd rather be tapping on a wooden surface if possible.

So far, then, the best sound is clean into the Fender, with a triple-folded dishtowel over the top and a pair of balled up gymsocks directly over the bottom-mounted piezo inside.

I should add that, so far, all testing has been performed with the box flat on the carpet, with bare feet. Raising the box on some feet would bring the resonance of the bottom of the box into play, but since my best results seem to be with damping the box out as much as possible, that sounds like a step backwards.

I'm thinking that maybe I should sacrifice a furnace filter and use the filter medium to completely fill the box.

|

|

|

|

Post by ashcatlt on Mar 24, 2010 21:15:06 GMT -5

When you said: However, moving the socks so they directed compressed the piezo element sounded better- a bassier sound, but pretty well damped out. I thought hockey puck. Can't tell the exact dimensions from your pics, but it seems a hockey puck must be pretty close to fitting in there... Then you said: I thought low-pass filter. The same thing is likely to happen if you turn it up far enough even without distortion. I agree that "acoustic" solutions to the overall tone are probably best, but if you're going to need a filter to make it practical, you'd ought to at least consider it's effects on the final tone. That is, if you muffle it till it sounds good, then add a filter, it might just turn to mud. Then you said: How bout some thin weather-stripping or that foam tape stuff? This could both tighten up the box when you close the latch and keep the two halves from hitting wood-on-wood when closed. Just throwing out ideas and living vicariously.  Hope it helps, or at least inspires. |

|

|

|

Post by newey on Mar 24, 2010 21:25:05 GMT -5

That's the kind of thing I was thinking about.

And a filter may be the way to go. If I get it too damped out for the filter, well, everything is temporary and removable for the time being.

The thing is ultra-sensitive to touch, even brushing up against the cable several feet away from the box produces a rustling sound. Maybe I need to try isolating the piezo element a bit from the surface of the box, rather than damping out the box so much. A piece of old inner tube rubber or maybe a Trojan would probably do the trick . . .

|

|

|

|

Post by JohnH on Mar 24, 2010 22:03:09 GMT -5

My understanding is that the piezos produce a signal in response to pressures that squeeze them. My thought about this is:

At low frequencies, the piezo is basically just going for a ride moving with the vibration of the top. The piezo xtal does not really get much pressure on it, or through it. So I think it would help if the underside of the piezo has some mass on it, like a stack of coins, so that there is some inertia there so when the top vibrates, it requires some pressure through the piezo to get that mass moving or to push against it.

A bundle of socks acting as a spring pushing up under the mass may still help.

John

|

|

|

|

Post by gumbo on Mar 26, 2010 1:30:58 GMT -5

Newey, also have a think about the way that piezos are installed when one converts an acoustic drum kit to an electronic one (Search A2E conversions on the V-Drums Forum, if you like!)...basically the underside of the drumhead that is being hit, contacts a foam rubber cone, the apex of which sits under the drumhead while its base sits on top of the piezo...the piezo itself usually being supported on bracketry within the drum shell. To be able to thus transfer the impact to the piezo while insulating it from the drum shell and rim seems to work for most people...ok, in this application it is the piezo signal being shunted to the input of a 'drum brain', whereupon quasi-midi kinda takes over, but you could just find some valuable hints from these things....having played around with electrifying hand-held shakers in recent times.....  Having looked at a couple of designs of stompboxes being made here in Oz, I also get the feeling that you would do better by starting with a heavier lump of wood to begin with...maybe consider two lumps that sandwich the piezo...adjust the 'feel' by the insertion of layer(s) of felt(?) between them maybe.... ...hmmm ...good luck - look forward to the thump samples... ;D |

|

|

|

Post by newey on Mar 26, 2010 5:49:04 GMT -5

Thanks, guys! Several ideas in there that sound promising. Basically, add mass around the piezo and isolate it a bit from the box.

I'll have to give some of this a try. Problem is, any of these methods would seem to be moving beyond a strictly temporary, "trial run" mounting. Hard to figure how I could mount it in/on wooden blocks, etc. without more or less permanently altering things.

|

|

|

|

Post by JohnH on Mar 26, 2010 13:39:43 GMT -5

I reckonthat for a test, you could have a wooden interia block, with a small hard rubber or plastic pad on it that presses up under the piezo, supported temprarily by sockage, the piezo being taped to the underside of the box top

John

|

|

|

|

Post by newey on Mar 28, 2010 8:31:17 GMT -5

Well, I haven't had the chance to do more with the mounting of the piezo. But I did try it into my bass amp, which has more EQ ability than my guitar amp. Ash suggested a low-pass filter would help, so I tried it with the bass pot at 100%, and the mids and treble all at zero.

This produces a satisfying Thump, so EQing it helps a lot. There's a bit of boominess, which I figure that the suggestions about the piezo mounting may cure.

But playing with it in this set-up, it looks like a winner. Only problem is that my bass amp is a bit underpowered for this- I would need more volume for anything other than practice (which is all it's going to be used for, for the present, anyway)

|

|

|

|

Post by newey on May 10, 2010 20:51:14 GMT -5

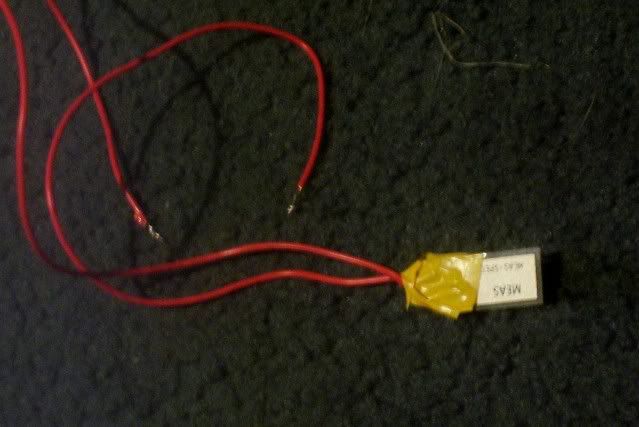

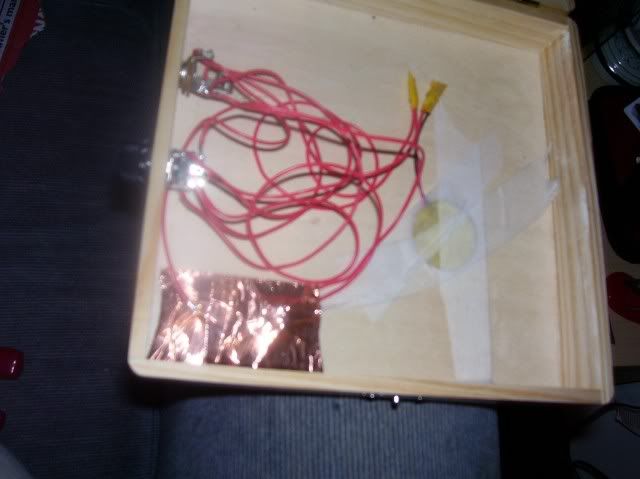

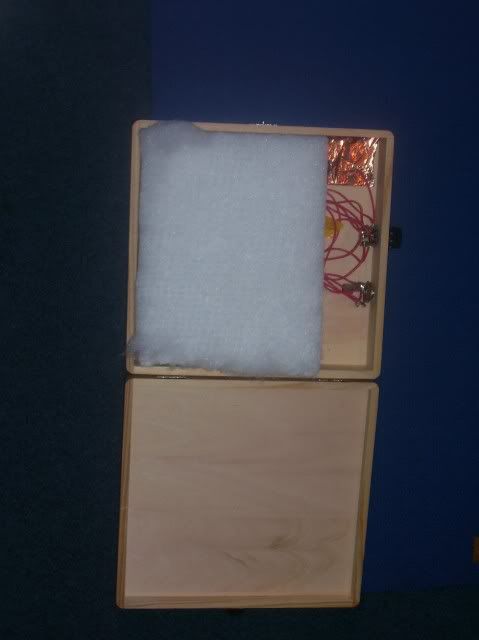

So, I revisited the stompbox experiments. I hadn't got back to it because I've been too busy stompin' on it! Anyway, to revisit, I wanted to add the second piezo, which is a polyfilm PVDF type. It's tiny compared to the piezo disc. And I had also held off on this because I figured I was going to need a very fine gauge wire to connect to these. But I elected to try it with regular 22 gauge wire since that's what I had . . . Big mistake, I should have listened to my instincts. IOW, this whole post is the tale of an Epic Fail. But do read on, please! Here's a photo of the innards prior to the install. The existing piezo disc is as it was, wired to the Vol and jack. You can see the conductive copper shielding tape installed for the new pickup, with a layer peeled back which will mount the pickup.  Here's a terrible photo to show the size of the PVDF pickup, next to the regular piezo and a nickel for size.  So, I started out by soldering leads to this PVDF pickup- This is the equivalent of trying to solder to a baggie. The metal leads just seem to be mounted into this plastic film, and even a tiny bit of heat started melting the whole damn thing. Being super-careful, I managed only to basically melt the crap out of the thing. Here it is after soldering/butchering, with a piece of yellow tape covering the leads to prevent contact with the shielding:  I had pretty well decided that I had destroyed the thing, but I did get 2 leads attached and so wired it in to give it a try. And- no signal from the new pickup. The existing piezo still works fine, but the new one is likely junk after my soldering fiasco. I have a second one of these, I have started buying duplicates of all components I purchase so as to have a spare for just such eventualities. But I need to find a better means of attaching leads to this. I suspect in its usual use, it is either micro-soldered in some fashion, or mounted to a plug on a board. There were no instructions with this, so who knows? Anyway, this is what it looks like with the new pickup encased in its copper condom and all wired up- and not working! The wire which is routed under the pot is the ground wire from the shielding to the jack. While the website had no instructions, it did mention that these needed to be shielded due to their ultrawide frequency response.  After this failure, and resolving to press on soon, I did retire the pair of gym socks I had inserted into the box for dampening. I substituted a piece of upholstery foam from a long-ago chair seat project, cut to size.  This did further help the original piezo sound, it's now sounding less like a knock on the door and more like a drum of some sort. I also still need to permanently mount the disc piezo, and also to get a deep-barrel jack to go through the wood properly. |

|

|

|

Post by ashcatlt on May 14, 2010 19:17:20 GMT -5

newey - I didn't noticed you'd updated this thread. I came looking to link to it for a guy over on the TOMB who's doing something similar. When soldering to heat sensitive components (diodes, transistors, ICs...) it's a good idea to put some relatively large piece of metal between the soldering point and the body of the component as a heat sink. Alligator clips are great for this. Looks like you might even have some trouble fitting one in there with what you're doing, but maybe one of those miniature ones at least? HTH |

|

|

|

Post by sumgai on May 15, 2010 1:27:19 GMT -5

newey, This will more easily satisfy the need espoused by ash:  as found here. They can be found cheap or expensive, all depending on your mood for that day.  I've got 4 or 5 pair just for this kind of job. No, I don't use them all on one lead, but I might rig up several leads at once, then solder them all at one whack. Depending on my mood for that day.  HTH sumgai |

|

|

|

Post by cynical1 on May 15, 2010 11:06:00 GMT -5

..so THAT'S what you're supposed to use those things for...

|

|

|

|

Post by sumgai on May 15, 2010 12:00:28 GMT -5

c1, No, that's what we professionals call an ancilliary usage. I'll leave it to your superior sleuthing abilities to determine the primary usage, as designed and intended.  sumgai Hint: The medical profession operates under a grand illusion that somehow it's in charge of technology. However, I think you'll find that their behavior falls squarely under several of "The Toddler Laws". |

|