|

|

Post by cynical1 on Sept 12, 2011 20:40:53 GMT -5

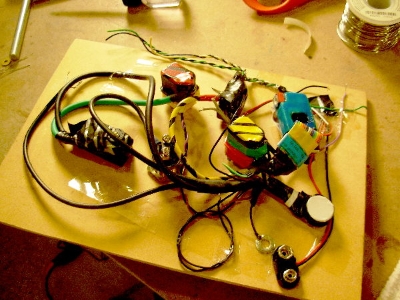

Ok, so this isn't about pedals specifically, more about how to power multiple stompboxes without batteries or individual adapters. The motivation for this ventures is the untimely demise of my Digitech multiple effects processor. I now recall why I used to shy away from these things, as when they go they take ALL of your effects with them...so it's back to individual pedals again...but I digress... I found R.G. Keen's The Spyder - an Eight-Output Pedalboard Power Supply was all over most of the other forums and DIY sites. Here's the simple schematics:   Mr. Keen eludes to a special transformer for this device on the page linked above: "Go to weberspeakerscom.secure.powweb.com/store/magnetic.htm and go all the way to the bottom to find WPDLXFMR-1, which has eight 11Vac secondaries for powering 9V pedals just as shown in this article, and one 9Vac output for powering pedals that need 9Vac. At the time of this update, it sells for $15.00, which is a GREAT deal."I've looked around trying to get my head around this thing and found a few iterations made by other do it yourselfers:  This is one of the transformer Mr. Keen mentions:     So, my question is, for someone who understands enough about electricity to know he can't beat it in a fair fight...is this something I should try? Or, is there a better mousetrap I haven't found yet? Thanks in advance for any assistance offered. Happy Trails Cynical One |

|

|

|

Post by newey on Sept 12, 2011 22:56:53 GMT -5

I have one of these: Godlyke Power-all. The link is to the deluxe version, which can do 11 pedals from a single wall wart, the basic version that I have does 5 pedals out of the box, but is expandable with added cables. Adapters to all the standard pedal power inputs are included, as well as a 9V battery clip adapter for any pedals that are nonstandard or which were battery-only to begin with. It's $30 for the 5-spot version. If the necessary transformer for the DIY version is $15, I doubt you could build one for the price of buying one. The DIY version will also be bulkier and probably less reliable. I've had this for a few years now, and it's been trouble free (although, granted, I'm not gigging with it.) Now, of course, if the point of the exercise is to learn how to build one and cost isn't the main consideration, then that's a different story. I also note that the DIY project allows for combining outputs to 18V; I'm not sure whether that can be done with the Godlyke unit or not, never looked into it. But to just power a bunch of 9V pedals it works fine and is pretty cheap, considering how many 9V batteries $30 will buy (not many). |

|

|

|

Post by cynical1 on Sept 12, 2011 23:47:55 GMT -5

I've seen those before...cats love them... But what really caught my eye was the grounding in the DIY box. I have an issue with this house...mainly because Ray Charles and Stevie Wonder wired it...with very poor grounds. I have two places in the house I trust...and even they can become noisy with too many things sharing the same ground via a power strip, especially through the effects loop on the amp.

Read the linked page and see if it strikes you the same way.

HTC1

|

|

|

|

Post by ashcatlt on Sept 13, 2011 0:14:05 GMT -5

I think it's overkill. I play in some pretty funky places and my tuna can power supply (scroll up for details) never adds enough noise to mention. Plug the wallwart into the same power strip as your amp and there usually won't be a problem with ground loops. None of the pedals I own care about regulated power, and the caps I use are plenty to smooth the power rails. Do you need anything other than 9VDC out of this thing? |

|

|

|

Post by JohnH on Sept 13, 2011 4:26:06 GMT -5

For pedal power, I just use a 1A stabilised wall wart and a daisy chain wire. Ive noticed no ill effects running, say a tuner, delay, chorus and overdrive for example. The wart was designed for my Zoom G2 processor and is quite small.

John

|

|

|

|

Post by thetragichero on Sept 14, 2011 13:21:26 GMT -5

yeah i used the one spot wallwart and a daisychain cable, currently running four pedals on it, and haven't noticed any ill effects, even when recording

|

|

|

|

Post by Teleblooz on Sept 14, 2011 19:32:02 GMT -5

The Visual Sound 1-Spot works well for me too. Current board is 5 stomp boxes, but I've used it with as many as 8 with no ill effects. And you can't beat that $30 price tag.

|

|

|

|

Post by sumgai on Oct 3, 2011 2:39:26 GMT -5

Seems to me that no one has yet addressed a direct answer to the question: So, my question is, for someone who understands enough about electricity to know he can't beat it in a fair fight...is this something I should try? I'd say that this is a very good Beginner Level project. Two thoughts: One, the specified regulator is rated for only 100mA, a mere 10 th of ampere. This might work for some dinky pedals, like single transistor distortion boxes, but most things could easily run to 250-500mA power draw. My Digitech RP3 needs nearly 800mA (but that is a multi-effects unit, which means a lot more active circuitry inside). If you think you're gonna run up against this kind of "limitation", be sure to check back here for more info. Two, depending on how much current (power) passes through this contraption, there might be a heat issue. Case ventilation might be in order... plan your enclosure and the physical layout accordingly. Other things might come to mind, I'll try to post them as they appear.  Well, I believe that's what everyone else was trying to do above, offer the alleged better mousetrap, in the form of a commercial unit. I went another way..... As far as a dead-simple power supply goes, this be the shiznitz. Only an Engineer could demand more from the design, under the pretense that it would catch more mice. Trust me, t'ain't necessary to go that far!  Or IOW, KISS, baby! ;D HTH sumgai |

|

|

|

Post by cynical1 on Oct 3, 2011 8:12:46 GMT -5

Seems to me that no one has yet addressed a direct answer to the question: So, my question is, for someone who understands enough about electricity to know he can't beat it in a fair fight...is this something I should try? I'd say that this is a very good Beginner Level project. Well, that's encouraging. I hate burning batteries and wall warts just don't do it for me if I'm going to build a pedal board. This thing appears to be a simple incorporation into a simple pedal board design. The reason I'm looking into this is that when my modeler went I realized that when these things go they take all of your effects in one fell swoop. For that reason I find myself gravitating back to simple stomp boxes. As I understand it, if these things will power off of a 9v battery, then the 100mA should be more then sufficient, although the standard Digitech power adapter is rated at 9.6V 250mA as I recall. Correct me if I'm wrong, but isn't a standard 9v battery putting out around 20-50mA? I didn't check the outputs from the transformer, but how would bumping the regulator up to say 250mA significantly effect the other components in this circuit? If I ever did run into rack mounted stuff I would stick to the ones that have their own internal power supply. Go big or stay home. I was thinking about powering 6 pedals from this box. I thought of taking one of the pairs off of the transformer and stepping it down to 5v and running a laptop fan into the case. This seemed like a useful endeavor. Thanks for the insights, SG. Glad to have you back. Happy Trails Cynical One |

|

|

|

Post by ashcatlt on Oct 3, 2011 9:35:39 GMT -5

Well, that's encouraging. I hate burning batteries and wall warts just don't do it for me if I'm going to build a pedal board. This thing appears to be a simple incorporation into a simple pedal board design. Naw, while it's not rocket science, it is more complicated then necessary when a resistor and a few caps would likely do the same thing just fine. Remember that the design from my Tuna Can is an exact copy of the supply on a commercial pedal board. As long as the transformers can handle the current, all the rest of the components stay the same. |

|

|

|

Post by sumgai on Oct 4, 2011 1:28:42 GMT -5

Well, that's encouraging. I hate burning batteries and wall warts just don't do it for me if I'm going to build a pedal board. This thing appears to be a simple incorporation into a simple pedal board design.

Naw, while it's not rocket science, it is more complicated then necessary when a resistor and a few caps would likely do the same thing just fine. Remember that the design from my Tuna Can is an exact copy of the supply on a commercial pedal board.I'm afraid I'm lost. ash, are you referring to power supplies in general here? I mean, are you implying that in many cases (if not most), that a "simple resistor and a cap or two" can/should replace a voltage regulator? (I hope I've misconstrued your intent, but I have to admit that at the moment I'm too lazy to seek out The Tuna Can ® to check what you put in there.) You know, don't you, that if my interpretation of your statement is correct, then we'd have to stand by helplessly as we watched a whole can-ful of whoopass get blasted open right in front of us...... |

|

|

|

Post by ashcatlt on Oct 4, 2011 10:47:47 GMT -5

I'm saying that I've never encountered a case where I needed a regulated supply for a pedal. Neither have I ever encountered a situation where any pedal chain (you have seen some of my pedal webs, no?) had a noticeable ground loop which would be solved by the transformer isolated outputs on this thing. It's good, thoughtful design, but it's overkill. You do need some transformer to knock the 120V down to somewhat more than 9V, and a bridge rectifier to get the AC line voltage to DC for the pedals. These are generally included in the wallwart, and could easily be removed and jammed in the box if you'd like. Beyond that, IME, all that's required is some good filtration. A resistor and a couple caps. |

|

|

|

Post by cynical1 on Oct 4, 2011 13:32:19 GMT -5

I also have an ulterior motive for trying this design. If it proves stable, and can be built into the pedal board, it could also be used to power on-board guitar devices, as in Sustainers, piezo preamps or MIDI devices, without batteries.

And the transformer detailed in the first post: "https://weberspeakerscom.secure.powweb.com/store/magnetic.htm and go all the way to the bottom to find WPDLXFMR-1, which has eight 11Vac secondaries for powering 9V pedals just as shown in this article, and one 9Vac output for powering pedals that need 9Vac.", which is now $25.00, should do the trick.

If this transformer can give me a box that powers 5-6 pedals and two on-board guitar effects it seems the $35.00-$40.00 is more then worth the price.

HTC1

|

|

|

|

Post by sumgai on Oct 4, 2011 19:49:23 GMT -5

c1, That xformer will do the job, unless you get really outrageous with the number of pedals...... BTW, the original link is now null and void. Instead, you'll have to visit: taweber.powweb.com/store/magnetic.htmThe desired unit is the fourth up from the bottom. (The third ond up is an international-voltage unit.) And as it happens, I checked over the circuit once again, just for drill, and realized that something isn't marked at all, something that will bite you in both the as-built device, and your wallet. Those capacitors should be marked as electrolytic units, both of them. The positive lead (the plus sign) goes toward the positive voltage, the negative side goes toward ground.. HTH sumgai |

|

|

|

Post by cynical1 on Oct 4, 2011 21:14:56 GMT -5

Back to the mA thing again... If the 78L09 voltage regulator is 9v positive at 100mA, is there a standard numbering convention that will allow me to step up to a 9v positive at 250mA or 500mA regulator? Or is that too simple?

HTC1

EDIT: OK, I figured out that the "L" is for low output, so a 7809 will give me up to 1A at 9V. I'll probably never us that much, but that leads to another question. Through hole versus surface mount. Aside from the heat sink properties for the through hole, are there advantages to using one over the other?

|

|

|

|

Post by 4real on Oct 5, 2011 15:35:47 GMT -5

I also have an ulterior motive for trying this design. If it proves stable, and can be built into the pedal board, it could also be used to power on-board guitar devices, as in Sustainers, piezo preamps or MIDI devices, without batteries. HTC1 I've tried these kinds of things but without too much success and there is some potential risk. The last time I tried building a pedal board, I used a couple of wall wart type things...one that was fairly generic and run most things happily, and a specialised one that was highly regulated for my digital delay and other such things that don't like to share or have any power irregularities. I built it in two 'tiers' so that these things could be hidden under the rear upper layer of boxes with a powerstrip that has a safety switch in it. An extension chord could be used for the distance to the output socket. Behringer make a decent wall wart thing and multi effects power for cheap and as long as protected so it won't get kicked around might be enough. You might even be able to afford a spare, just in case. These things are compact but do the job. I've burned out too expensive boss supplies over the years, to the point I stopped using effects all together which is a shame cause a lot need to be powered. .... The word sustainer of course grabbed my attention, and piezo given my current project. There are problems with powering on-board electronics, especially sustainers that you need to think about there...not to mention the risk of having your guitar wired to the mains...just saying....hmmm A sustainer is running a small power amp and while not completely tested, the idea of running a stereo cable, sharing the power and signal ground and a positive power lead, sounds attractive...this kind of circuit does tend to draw a bit of power and can create a bit of a racket running right along side the signal all the way to the amp. I was playing with the idea but never got that far. Others have tended to using a separate power cable (variax does this too I think) which is a hassle. In my sustainer designs, which are pretty simple, the battery is a part of the circuit too, it provides a kind of natural limiting to things. It will work off a wall wart, but it can draw as much power as it likes so you might need to have some i built limiting in the sustainer design so the feedback loop does not get out of control. The thing is though, when you turn the sustainer off with that power load, this sudden drop will create a noise in the signal and shared ground running along side it I would suspect...you don't want a 'clunk' every time the sustainer goes off. I believe it is a scheme that work ok for low powered onboard pre-amps and piezos that are on all the time or use very little power. I figured that carrying a spare battery was probably the go for such devices that can be on for days. |

|

|

|

Post by cynical1 on Oct 5, 2011 17:44:35 GMT -5

All good points to be considered in the design.

What got me inspired to work this out was the work I was doing for the Dept. of Corrections. We used IP cameras and POE (Power over Ethernet) pushing up to 15 vDC to digital cameras some 300' from the switch through common CAT 5e and CAT 6 cable. No noise or loss of video or audio was experienced from any of these installations, so I figured why not work this out for a guitar no more then 25' from the power source.

And I see this as a specialty cable assembly with a division between signal and power and probably utilizing a locking or threaded heavy duty connector. The pinouts for the power and the audio can be worked out after the box and the on-boards for the guitar are finalized.

And while I don't consider myself an expert at this by any means, I still think it's doable.

Something else I was looking at was one power feed to the guitar with a DC to DC converter. This may require some additional filtering, but it's something that can be isolated from the individual devices and could conceivably power 9v to 18v on-board devices.

Again, this is in its infancy, but I don't think it's impossible...yet...

More research on dealing with the clunk appears in order, because a sustainer will be part of the guitar design.

But the end objective remains the same. No batteries and clean isolated power to all devices in the signal chain.

Thanks for the insights.

Happy Trails

Cynical One

|

|

|

|

Post by 4real on Oct 5, 2011 18:28:36 GMT -5

Oh...I think it will be do-able and problems overcome...

I'd be a little concerned with guitars like this that if anything goes wrong with say the power supply or it's systems, that the whole thing might go dead.

I considered this a bit with my sustainer designs, electing unlike all others that I know of, to have the guitar completely passive when the sustainer is off...but that's me.

In the new project that contains a piezo and a bunch of pre-amps, I am looking at perhaps a direct out for the mag, just in case.

I'll be interested about your cabling solutions though. In this project I am considering a third pickup system (hex out, harmonized) and it will be likely that an option to have separate outs through one cable to some kind of splitter box, possibly with power to the effects on the end of the chain will be in order...who knows, perhaps even the guitar as the systems are mounting up for this deceptive monster LOL.

So, is this a preview for a new guitar project?

...

Be careful working with mains electricity things...I once welded a soldering iron to a transformer and took out all the power in the house via the safety switch. I since found cheap 4 plug safety switch powerboards and use that usually (even though the house here is protected) a lot of the time and carry one in the back of the amp for when I am playing away from home.

Being electrocuted is a shocking experience, and the way the guitar is set up it can conduct right across the heart, so not a good thing. I got a zap years back in a band from an old bass head we were using for vocals...zapped me right in the kisser...not pleasant LOL

|

|

|

|

Post by cynical1 on Oct 5, 2011 23:26:57 GMT -5

I'd be a little concerned with guitars like this that if anything goes wrong with say the power supply or it's systems, that the whole thing might go dead. I agree completely. I also want the guitar to be fully functional on its own in a passive state. And you make a good point. One of the first things to overcome is the requirement that Fernandes has on their circuit being in the loop 100% and in a no power situation the passive pickups go dead as well. And I'm still debating on whether to pull the MIDI output from a hexaphonic pickup or from the piezos in the saddles. But that's just one more thing on the list. In a previous life I worked with engineering OEMs and manufacturers to spec and design control and package handling equipment. Over engineering something is a genetic trait, and this will be no exception. I'm not looking to build a Rolls here, but I plan on going as "industrial" as possible with the component specs. Everything on this guitar and the related components will be top of the line with no marketing feldergarb or unobtanium included. Actually, this is probably going to be a bit more then that. ChrisK and a very short list here know most of it. I have the good fortune lately to be working with an electrical engineer that also builds Moog equipment, scientific reference microphones and other electronic wizardry and runs the website Grove Audio. OK, so that was a shameless plug...I apologize...but he's a good man and this economy isn't doing his business any good. And I make no money from this, so the plug is from the heart. The ugly truth is that the final intent is to get back in the game. Being broke has become so second nature after 7 years in Wisconsin that I'm toying with the idea of building guitars again. Best way to stay broke is to work for yourself, right? So, be advised, this is part of a potential commercial venture and I will do my best not to scam you guys for free insights. This will take some time to get off the ground, but I'll share what I can without giving the store away. The guitar is basically a chambered take on a modified Jazzmaster style body. The intent is to backrout the body and bury all the goodies inside of it so from the front it appears like any other guitar. As I've said before, I have a healthy respect for things I can't beat in a fair fight. The isolated power circuits are based on the design posted above. There is more filtering and a slight variance in the actual components spec'd. There are also plans for adding additional ports and interfaces out for manipulating the signal, but that's still under my hat. I'm not looking to make money on the "magic" box, and it will go for cost plus labor in the final product. I can't compete on price for the low end, but I can be competitive in the higher end market. At least that's the plan. Well, the cat's out of the bag now. And it really has to be, as I don't want to give the slightest impression that I'm picking peoples brains for free here. Happy Trails Cynical One |

|

|

|

Post by 4real on Oct 6, 2011 0:30:01 GMT -5

Ahh...I see...it can be a rocky road there and good luck. I might as well share my experience with such a venture now the cat is out of the bag from the builder who told me to keep it secret... I did the sustainer and wiring for this guitar, now in the hands of Tom Morello and all the wiring was done remotely by me a couple of years ago...    www.guilfordguitars.com/the_goblin www.guilfordguitars.com/the_goblinThis was a prototype for the commercial version of my 'sustainer system' called the "firedrive"... It used a wafer coil that could retrofit to a strat type neck pickup. Seymour duncan unwittingly made the custom neck pickup. I wired the whole thing on a mock guitar over here and was to get a 'cut' of the final cost of the guitar. This thing is an extremely high end custom, but the real reason to do it was to get the guitar in a high quality instrument and test the waters a bit... In the end, well...it cost me money. The guitar was accepted, as a gift...so a percentage of nothing is...hmmm...well to be fair I was apid a little but that only just covered the insurance to send it half way around the world. It was a rewarding project with some interesting ideas and some insights into this kind of business. The guitar had toggle and push button kill switches and an option for the toggle to run something we were calling a "maim switch". basically, an extreme tone control, didn't kill the signal, just the treble...so kind of like a passive wah kind of thing. Besides me moving to the island, for various reasons, I just could not see the numbers adding up on the sustainer thing in the short term or possibly the long. It would be impossible to afford patents, let alone the lawyers to defend it from across the waves. I did of course seal everything in an epoxy block, but some things you really can't hide there. In fact, my strat was also to have a sustainer in it too (remember my "uber switch pots"?) and the neck pickup and middle pickups still have a sustainer coil fitted (cant see it, so why take it out LOL) and LED's to light up discretely (the middle one was to indicate the piezo system was on. Happy to give my experiences in some of this if useful off site. I might say though, that I ran into John G through the sustainer reputation and because I bought a pair of lovely flame maple pickup rings off of him on eBay. One will be used on my new project and will really look good, being close to the colour of the top. ... I'd like a midi capable guitar, mainly for transcription perhaps recording. Not sure of the market of course. I always wondered why the variax didn't take that step... The ghost system is pretty good for a piezo midi set up and these days, I'm inclined to think that a piezo is more the way to go. It's hard to know where these things will go, the guitar market can be fickle but the higher end and speciality market is probably the way to go there. Even then though, it is competitive. I could get the cost of the thing down, developed jigs, coil winders and such to make it possible, had future plans for a MK2 with the circuit built in SMD taking that side of things out of my hands...but, big risk and likely little rewards for such a part...though I am always helping someone with the DIY version over email for nix. I've already lost too much in the project I figure, though the infrastructure is still there. I know or know of a few builders and there are some remarkable successes out there in the high end custom one of a kind type of market from what I can see. But there are some incredibly talented builders but there that can't make a cracker with affordable and top line guitars...so what can I say, good luck and make us proud (plus if it is an instrument that you want for yourself, there is no foul in a prototype, that's all I do these days with guitars!) |

|

|

|

Post by cynical1 on Oct 6, 2011 8:20:44 GMT -5

Thanks for the well wishes. I'm gonna need them.

And you're absolutely right. The guitar buying public is a fickle and unpredictable bunch. And with the economy what it is currently working on the prototype is about the best use of my time and slim resources.

And getting your guitar in the hands of someone of some notoriety that will give you some exposure is also a costly prerequisite...however, when it never sees the light of day or is gifted off it sucks.

That is a beautiful guitar you've got your system in. Probably too beautiful for Morello...this is the guy with "Arm The Homeless" stuck on one of his stage guitars...

I agree that most MIDI systems out there now are more for the studio and not practical for live shows. I think most of this is the weak link in the cabling and device powering systems. With luck I can find a more bombproof way around that Achilles Heal.

Part of me would like to take the road less traveled on the components, but when folks like Fernandes, Roland and Axom have spent such an impressive amount of money of marketing and advertising, it just seems like the simplest route to go by spec'ing their parts in the guitar.

And if it all goes to Hell in a hand basket, at least I'll have the prototype to dink around with.

Happy Trails

Cynical One

|

|

|

|

Post by 4real on Oct 6, 2011 8:48:50 GMT -5

Absolutely...there is of course the concept of prior art if you publicly have already such an instrument  makes it harder for someone to steal ideas and patent them as their own...just a vague thought...no money in it though. I'd always hoped someone might run with the idea that are better equipped to deal with it, ah, but not to be. I am in the same boat I am afraid, but some ideas just need to be expressed and then to see if anyone is interested. I just posted some thoughts on hex pickups using tape heads if interested. This is how roland originally did their guitar synths. There is some potential in this concept beyond the application that I am intending I am sure. John G is a great custom builder, back in 2008 he was looking at giving up and of course we made nothing out of what was potentially a very expensive instrument (I was always dubious about such an ostentatious looking quality instrument for that artist myself, but it is a fine guitar). Looks like he has climbed out of it a bit with guitars hanging in different shops and a line of instruments and all. Times are tough for a lot of people, but on the other hand...there has never been a bigger discrepancy between the haves (and I would suggest that Mr Morello is doing ok) and have nots. The same is all over...perhaps some of those wall street bankrupts might cough up for a unique instrument. I've got no commercial applications for my current ideas, but it is still a worth while pursuit to create something unique...it is kind of what this site does best. Creating a radically different instrument, a concept guitar, is a really great thing to do. If just one feature is successful, you are on a win if it can do something unique. You could be right about the midi thing. It has come a long way. There are quite a few people who would want that capability I would thing, even if synth guitars never quite took off. Just having the hex thing has a huge potential for some new sounds. You may well be right about a stageworthy guitar and the power thing is probably best custom built for the purpose if there is a bigger concept in mind. You might want to consider the possibilities of using a computer on stage even, as this is becoming more common. I've been helping a guy over there with a sustainer lately who plays in a super controlled environment with pods and something called a 'butt-kicker'...someone like that may well be attracted to such an instrument, so you never know! I love bringing one of my concept guitars to a successful conclusion and that in itself is a reward, though frustrating along the way. I'm only a quarter of the way through this one and there is no electronics in it yet...or even a proper bridge...but it's way past midnight here and I have not been able to put it down all evening...now that is the sign of a great guitar right there! |

|

|

|

Post by sumgai on Oct 6, 2011 23:36:37 GMT -5

c1, OK, I figured out that the "L" is for low output, so a 7809 will give me up to 1A at 9V. I'll probably never us that much, but that leads to another question. Through hole versus surface mount. Aside from the heat sink properties for the through hole, are there advantages to using one over the other? Unless you are morally certain that you will be powering devices that do require more than 100mA, then you can, and perhaps should, stick with the L designated units. Price, size of the enclosure, all that kind of stuff. Which then says, to the cognoscenti, that you can plan ahead. There's nothing sacred about using all the same type, is there?  Designate some fraction of the total number of outputs as low-power, and the rest as "overpowered", and plunk in the required regulators.... now you should be pretty much prepared for anything, but without raising your cost above the ridiculous, nor causing your housing to become larger than your guitar. But if you do this, be sure of your front-panel labeling!! HTH sumgai |

|

|

|

Post by cynical1 on Oct 7, 2011 10:51:40 GMT -5

Unless you are morally certain that you will be powering devices that do require more than 100mA, then you can, and perhaps should, stick with the L designated units. Price, size of the enclosure, all that kind of stuff. Which then says, to the cognoscenti, that you can plan ahead. There's nothing sacred about using all the same type, is there?  Designate some fraction of the total number of outputs as low-power, and the rest as "overpowered", and plunk in the required regulators.... now you should be pretty much prepared for anything, but without raising your cost above the ridiculous, nor causing your housing to become larger than your guitar. But if you do this, be sure of your front-panel labeling!! I was thinking about that. Would it be worth tossing in some variable regulators and some resistors to offer a 500 mA option, or would leaving it at 1A server the same purpose and eliminate the confusion and complexity...and cost? HTC1 |

|

|

|

Post by sumgai on Oct 7, 2011 11:42:00 GMT -5

Would it be worth tossing in some variable regulators and some resistors to offer a 500 mA option, or would leaving it at 1A serve the same purpose and eliminate the confusion and complexity...and cost? Reglators of this type are meant to be used as voltage controllers, not amperage controllers. (However, controlling amperage can be done, albeit at a greater expense in parts count and complexity.) If you are looking for a variable voltage unit, such exists in the form of an LM317, but is probably not needed here. All of that said, the transformer itself is rated to handle only 300mA per winding output, so a standard 7809 with a very small heatsink would still be overkill, but necessary due to the maximum allowable power rating of the 78L09. Seeing as how you're starting to leak details of your project, I'd like to gently caution you that some potential buyers are gonna want to use an RF cable....... Just sumpin' to keep in mind, tha's all.  HTH sumgai |

|

|

|

Post by cynical1 on Oct 7, 2011 14:27:28 GMT -5

...I'd like to gently caution you that some potential buyers are gonna want to use an RF cable....... Just sumpin' to keep in mind, tha's all.  Are we talking RG-6 coaxial cable, or the high bandwidth stuff...or something else? HTC1 |

|

|

|

Post by newey on Oct 7, 2011 17:05:41 GMT -5

He means 'radio frequency", as in a wireless system. Making the proposed transfer of power to the axe somewhat problematic, unless you have a Tesla-like solution for wireless power transmission in mind.  |

|

|

|

Post by cynical1 on Oct 7, 2011 17:48:39 GMT -5

Fair enough. Makes the mis-perceived coax reference less confusing...

And since it's a tethered system then it will become null and void on wireless, aside from the passive output. But as I understand it, with certain piezo systems the tethering is also a factor, so if you're a wireless only player then this won't work for you onstage.

Well, that's a demographic I don't have to spend money trying to woo.

There are enough people out there that cable in, so I'm not concerned about finding a fix for that, or adding batteries as a backup.

This system is going to be for those with an advanced mastery of their instrument and enough compositional theory to take full advantage of the MIDI system...without having to make continual monetary sacrifices to the Great God of Alkalines.

I may just be whistling in the wind on this one, but I believe if it's done with high quality components, first class craftsmanship and B-52 coffee maker durability then it should have a market...just not for those who go 100% wireless...

Happy Trails

Cynical One

|

|

|

|

Post by cynical1 on Feb 10, 2012 20:22:54 GMT -5

Well, I pulled the trigger on the WPDLXFMR-1 transformer from Weber.  This is a pretty good size piece of hardware, so concerning myself with designing a small enclosure for it went right out the window upon opening the box. I think it should still fit on or within a medium to large sized pedal board without too much difficulty. I've got my order in with John and Grove Audio for the balance of parts for this, so I'll get some shots of this as I muddle through it. I think I'm going to use SG's idea of setting high and low ma outputs. Any creative suggestions on what to do with the 9 vac 2A output? More to come... Happy Trails Cynical One |

|

|

|

Post by flateric on Feb 22, 2012 6:41:15 GMT -5

I have a need for a power box running off UK 240V AC to power a pedal board and give 3 different voltage outputs; its 9V needed for 4 stompboxes, then 12V for some LED strips and higher voltage (can't remember if its 18V or 24V) to power an EHX bass micro synth pedal. Where would I start?

|

|