tom

Meter Reader 1st Class

Posts: 51

Likes: 0

|

Post by tom on Aug 12, 2009 20:00:51 GMT -5

Hello All ! I'm back ! ;D So, now that my buddy's guitar is up and running, it's time to put together my own project. I have quite a few questions, but first, here's what I'm working with. . . 1) SSS Strat body (fully copper shielded) 2) Copper pickguard shield (Monte Allums) 2) heavily reliced neck with new Sperzels 3) Aged Synchronized tremolo, jack plate, and hardware 4) JB Jr. in the bridge, Dimarzio Area 61 in the middle, Dimarzio Area 58 in the neck 5) still wired VVT with 5 way switch from a "never used" Robert Cray strat I've read ChrisK's thread on "The Blocking Capacitor" (as well as many other opinions on "Quieting the Beast") and he states that using the capacitor is "better, not best". I know there are varying opinions on the "safety" issue, but I am building from the ground up, so I figure why not ? I always use a power conditioner in my rack and everything is plugged in there. And as per the article, I will from now on. . ."Use an outlet tester every time, use a GFCI cable every time, and use wireless every time."  1) I assume there is no "down side" to using the capacitor and wiring per the QTB, correct ? So, a few questions in the assumed order I would encounter them. . .(stupidest one first !  ) 2) When soldering the capacitor to the ring terminal . . .where exactly do you solder after crimping the end ?? Just at the point where the capacitor lead enters the connector ??  3) Any difference in using a heavier gauge braid + 2 wire conductor vs. the thinner (22G) wire that came with the Stew Mac copper shielding ?? 4) Is the current tone capacitor on the tone pot appropriate ?? How do I determine the value ? (It says ICMSR1 04K 250V S 817). 5) The JB Jr. instructions state Black to switch, Red and White soldered together and taped off, and Green and Bare to ground. So. . .Green and Bare together to the ring terminal/star ground/signal return ?? The instructions state to not let the Bare wire touch anything. . .so if it is a little longer going to the star ground, should I wrap it or put a piece of heat shrink around it (without heating it) ?? And two "unimportant" ones. . . 6) Has anyone used a JB Jr. with the Areas ? Just wire per instructions and reverse if bad ju ju ? 50% chance, but it states reverse leads for stock strat pickups (in my buddy's guitar), but the non "reversed" way was correct. (Glad I chose that one first !) 7) The JB Jr. sounded GREAT in my buddy's guitar, but it was slightly on the trebly side. . .to be expected from a "mini" humbucker. Any thoughts on moving the middle tone control to the bridge now or wait until I see what it sounds like first ?? 8) Any measurements or meter readings I should take while everything is disassembled ? You might gather that I ideally want to put this together "once". I know it's no big deal to go back in, but that's just me !  Sorry for the long post, but hopefully that covers everything !! I'm really excited to put this thing together as it is based on a Fender Custom Shop built for one of my favorite players and friends !! I will relay the story when I finish along with some pics. ;D I look forward to the flood of replies !  Cheers ! Tom |

|

|

|

Post by newey on Aug 12, 2009 21:01:29 GMT -5

Other than the work you put in and the cost of the cap, there is no downside. The use of a ring terminal is just so you have a convenient place to solder all the grounds onto. It becomes your "star grounding" point in the QTB scheme. You can solder the cap anywhere on the ring, or crimp and solder at the crimp termination. Try to solder towards the end of the wire lead from the cap, so as not to fry the cap in the process. Soldering is needed because the wire gauge is too small for a good crimp connection. (Come to think of it, "good crimp connection" may be an oxymoron anyway . . .) Are you referring to the 2 wire + braid cable going to the output jack? 22 gauge wire is fine for wiring up the rest of the guitar. Since your cavity is shielded, there's no need for a braided cable elsewhere, other than to the out jack. I don't know the code, so I can't tell its value. But someone will be along. You can't determine its capacitance without an LCR meter, as ChrisK is fond of reminding me.  An LCR meter is a fairly costly piece of equipment to have just for guitar wiring. As far as what is "appropriate", that's a pretty subjective subject. "Standard" Strat wiring generally uses a .022µf, but since you're changing the pickups you may want to consider other values, or experiment. Read ChrisK's thread on "Pickup Coil Response Tuning" for more info on this topic. There is also a somewhat meandering thread on Capacitors for guitars. ChrisK's article has to do with switching caps in/out, not specifically for tone controls, but the graphs give you an idea of what the variations will do. That's fine. Insulating any bare wires is a good idea so it doesn't hit any "Signal Hot" connections as you shove all your fancy wiring back into the control cavity and button down the guard. Heat shrink tubing or electrical tape will work fine. #6 and #7- I'm not familiar with these pickups in a "hands on" way, so I have no opinions on them. Switching the tone control from Mid to Bridge is a popular mod regardless of pickups used; the fact that Strats had no tone for the Bridge is a historical anomaly anyway. Measure the resistance of all the pickups outside of the guitar and record the measurements. This will aid in any later diagnostics, if needed. I do likewise with the pots. Other components should be checked to see that they are working and/or within tolerances. Live and learn on this, from one who has spent hours trying to sort out why my wiring wasn't working, only to find that the switch was bad. And don't assume that a brand-new part is in working order, or that the part that was just working in the guitar before you took it out is still good once you have it in your hand. Better to spend a few seconds checking against a 1000-to-1 shot failure than to have those odds smack you once it's wired up.   |

|

tom

Meter Reader 1st Class

Posts: 51

Likes: 0

|

Post by tom on Aug 12, 2009 22:14:44 GMT -5

Other than the work you put in and the cost of the cap, there is no downside. The use of a ring terminal is just so you have a convenient place to solder all the grounds onto. It becomes your "star grounding" point in the QTB scheme. You can solder the cap anywhere on the ring, or crimp and solder at the crimp termination. Try to solder towards the end of the wire lead from the cap, so as not to fry the cap in the process. Soldering is needed because the wire gauge is too small for a good crimp connection. (Come to think of it, "good crimp connection" may be an oxymoron anyway . . .) Are you referring to the 2 wire + braid cable going to the output jack? 22 gauge wire is fine for wiring up the rest of the guitar. Since your cavity is shielded, there's no need for a braided cable elsewhere, other than to the out jack. I don't know the code, so I can't tell its value. But someone will be along. You can't determine its capacitance without an LCR meter, as ChrisK is fond of reminding me.  An LCR meter is a fairly costly piece of equipment to have just for guitar wiring. As far as what is "appropriate", that's a pretty subjective subject. "Standard" Strat wiring generally uses a .022µf, but since you're changing the pickups you may want to consider other values, or experiment. Read ChrisK's thread on "Pickup Coil Response Tuning" for more info on this topic. There is also a somewhat meandering thread on Capacitors for guitars. ChrisK's article has to do with switching caps in/out, not specifically for tone controls, but the graphs give you an idea of what the variations will do. That's fine. Insulating any bare wires is a good idea so it doesn't hit any "Signal Hot" connections as you shove all your fancy wiring back into the control cavity and button down the guard. Heat shrink tubing or electrical tape will work fine. #6 and #7- I'm not familiar with these pickups in a "hands on" way, so I have no opinions on them. Switching the tone control from Mid to Bridge is a popular mod regardless of pickups used; the fact that Strats had no tone for the Bridge is a historical anomaly anyway. Measure the resistance of all the pickups outside of the guitar and record the measurements. This will aid in any later diagnostics, if needed. I do likewise with the pots. Other components should be checked to see that they are working and/or within tolerances. Live and learn on this, from one who has spent hours trying to sort out why my wiring wasn't working, only to find that the switch was bad. And don't assume that a brand-new part is in working order, or that the part that was just working in the guitar before you took it out is still good once you have it in your hand. Better to spend a few seconds checking against a 1000-to-1 shot failure than to have those odds smack you once it's wired up.   I'm not sure how to do the quotes on pieces of someone's post. . .sorry ! I hope you can follow ! 3) Yes, the output jack. That was a poorly worded question. The shielding came with a "shielded, 2-conductor wire", presumably for the jack. I guess my question was, is this appropriate to use or do I need the shielded wire with the braid and the second conductor ? 7) (moving the middle tone to the bridge). I may just put a jumper to do both the middle and the bridge. 8) Any nifty links on the "how to" you can point me to in terms of taking readings ??  Another question I forgot to ask. . .I would, in fact, have to remove the two "ground loops" as stated if doing this mod. . .correct ? Thanks for the info ! Tom |

|

|

|

Post by newey on Aug 12, 2009 23:01:14 GMT -5

Yes, or the safety cap won't provide its modicum of protection.

I think you are asking whether there's any difference between using a 2-conductor wire with a foil-type shield versus using a 2-conductor wire with a braided shield. It's tough to solder the foil shielding, so opt for the braided if you can. The braid can be soldered directly to the cavity shielding if you've used copper.

The regular Strat configuration has the anomaly of both tone controls interacting when in position "4" (N + M) on the 5-way. You'll have the same problem. If you make the tone control for the bridge only, there is no interaction since, as standardly wired, the bridge and neck aren't on together. Something to consider, anyway.

As far as measuring components, for pickups, set your meter to read resistance, in the 20KΩ range (unless it's an "auto-ranging" type). 2-wire pups are straightforward; for 4-wire HB pups, you can test them with the coils already wired together in series, for the overall series resistance of both coils, or check each coil individually, if your wiring is going to involve splitting the coils.

For pots, checking the resistance between the 2 outside lugs gives you the pot's value. Most guitar components are made to a 20% tolerance (not so hot but good enough for guitars), meaning a 250K pot should be ± 50K.

For switches, you're just checking for continuity in the various positions that should be connected, and for no continuity in those positions which should not be connected. No continuity shows infinite resistance, meaning an "over limit" or "out of range" reading; continuity means 0Ω or close to it. Some meters also have a continuity setting with a "beep" to indicate continuity.

BTW, to quote a portion of a post, highlight the part you want, and click on the "quote" icon in the "Add Tags" box in your reply window. It's the second from the right, bottom row, looks like a page with an arrow coming out of it.

|

|

|

|

Post by sumgai on Aug 13, 2009 13:03:26 GMT -5

Tom, You seem to be quoting just fine.  You said that the braided + 2-conductor wire was included in a kit. I have to ask, is that piece pretty much as long as needed, and not much longer? Reason being, you'd want to use just such a braided (shielded) 2-conductor cable in a situation where shielding the entire cavity is out of the question - semi-hollow bodied guitars such as the ES-335 come to mind here. It may be that other guitars have need of such, perhaps like running the cable from the control cavity up to the pup selector switch in a Les Paul style axe. That particular job would require about 2 feet of cable length. If the cable was/is short, say no more than 6 or 8 inches, then perhaps it is meant to be used with a Strat/Tele output jack. At that point, I'd agree with newey, above, in that after shielding the entire cavity (and pickguard), and the jack cavity too, that cable really isn't going to make much of a difference. I suppose that if one wants too, there'd be no harm in it at all..... So call me "non-anal", but I don't do that on my own Strat, take it for what it's worth.  (However, while I do twist the pair of 20 or 22 ga. wires together, that's just to make it easier to feed them through the hole between the cavities, not for any hum-reduction effect.) HTH sumgai |

|

|

|

Post by D2o on Aug 13, 2009 14:23:47 GMT -5

Hey Tom,

If you ever see something that you want to learn how to do, the best way I know of is to actually press the "quote" button and read the "language" behind the post that makes it look that way.

When quoting, just remember that the quote command must be the word quote , framed by a [ and a ] , and then you do almost the same thing to end the quote, except you use the word /quote , framed by a [ and a ] . You can quote and unquote over and over in any given post.

I hope this makes sense and is of some help.

Cheers,

D2o

|

|

tom

Meter Reader 1st Class

Posts: 51

Likes: 0

|

Post by tom on Aug 13, 2009 14:27:02 GMT -5

Tom, You seem to be quoting just fine.  You said that the braided + 2-conductor wire was included in a kit. I have to ask, is that piece pretty much as long as needed, and not much longer? Reason being, you'd want to use just such a braided (shielded) 2-conductor cable in a situation where shielding the entire cavity is out of the question - semi-hollow bodied guitars such as the ES-335 come to mind here. It may be that other guitars have need of such, perhaps like running the cable from the control cavity up to the pup selector switch in a Les Paul style axe. That particular job would require about 2 feet of cable length. If the cable was/is short, say no more than 6 or 8 inches, then perhaps it is meant to be used with a Strat/Tele output jack. At that point, I'd agree with newey, above, in that after shielding the entire cavity (and pickguard), and the jack cavity too, that cable really isn't going to make much of a difference. I suppose that if one wants too, there'd be no harm in it at all..... So call me "non-anal", but I don't do that on my own Strat, take it for what it's worth.  (However, while I do twist the pair of 20 or 22 ga. wires together, that's just to make it easier to feed them through the hole between the cavities, not for any hum-reduction effect.) HTH sumgai Guys, Let me try to be brief. . . Here's a link to the shielded, 2-conductor wire that came with the Stew Mac shielding kit. It's 20" long and I believe it's 22G. It looks nice and beefy in the pic, but it's pretty wimpy. . .I guess the camera really does add 10 lbs !  www.stewmac.com/shop/Electronics www.stewmac.com/shop/Electronics,_pickups/Supplies:_Shielding/1/Self-adhesive_Shielding_Kit/Pictures.html#details Here's something similar to what I'm used to seeing on the output jack. . .  I know it might not make much difference with the fully shielded cavity, but that wimpy Stew Mac stuff looks like something you might break the connections on with one accidental mishandle. I have some brand new RCA jacks (audio cable). . .should I just use that instead ?? I don't like wimpy, wimpy, wimpy !  Look at me with pic insertion !  Tom |

|

|

|

Post by D2o on Aug 13, 2009 14:33:42 GMT -5

Hi Tom, I get what you're saying, but so long as it is conductive, wimpy is fine. It even gets to hide in shame under the hood  I am sure the RCA jack wire is fine too. Here is one to mull over: ever since Wolf pointed it out, I have used solid core phone wire. I really like it. Cheers, D2o EDIT - nice pic insertion ... you're beginning to know your way around the "language" of these commands.  |

|

tom

Meter Reader 1st Class

Posts: 51

Likes: 0

|

Post by tom on Aug 13, 2009 16:00:31 GMT -5

I thought shielding the jack cavity wasn't recommended ?? It's a little tight, but it doesn't seem to be too difficult to do. . .

Tom

|

|

tom

Meter Reader 1st Class

Posts: 51

Likes: 0

|

Post by tom on Aug 13, 2009 16:18:40 GMT -5

Ok. . .I took some readings. . . I measured the JB Jr. from the circuit board underneath. Red to Green reads 7.67k (specs say DC Resistance 16.09 k). I guess this is both coils combined ?? The Area 58 Red to Green reads 5.09 k (specs say 6.15 k). The Area 61 Red to Green reads 6.27 k (specs say 6.43 k). The outer lugs on the Middle tone pot (on the 2M setting) reads .300. The outer lugs on the Neck tone pot (on the 2M setting) reads .252. The outer lugs on the Volume pot (on the 2M setting) reads .225. I'm assuming this is all ok. I'm not sure how to check the switch. . .  Thanks ! Tom |

|

tom

Meter Reader 1st Class

Posts: 51

Likes: 0

|

Post by tom on Aug 13, 2009 17:06:52 GMT -5

|

|

|

|

Post by D2o on Aug 13, 2009 18:46:29 GMT -5

Yep, I agree. Seriously, I really like the solid core phone wire. It's good, solid copper. It's cheap. It's readily available at any Home Depot, etc. It's easy to work with. It's easy to bend into any weird shape you may need ... D2o  |

|

|

|

Post by newey on Aug 13, 2009 18:53:28 GMT -5

Sumgai said: Tom said: I think SG was misreading me a bit there. I was trying to clarify exactly what you intended to do with the 2-conductor cable- output jack or other wiring? You clarified you meant using it to the output. I never mentioned shielding the jack cavity. That can be done, but you need to ensure that neither the tip of the plug, nor the tip connection, touch the shielding. If you use a shielded cable to the jack, it's superfluous to also do the jack cavity- a shield within a shield. The smaller wires- "wimpy" to you- are easier to work with, and plenty big enough for the minimal current running through a guitar circuit. And when it comes to feeding wires through the hole to the jack cavity . . .well, just try enlarging that hole sometime and you'll appreciate the value of smaller diameter wire. And previously: Twist the red and white together, and measure green to black and see what you get.  Assuming that these readings are in KiloOhms, and assuming they're supposed to be 250K nominal value pots, ± 20%, they are OK. Although, at 300KΩ, your Mid tone pot is at the outer limits of the spec. The assumption in all of the above, however, is that these pots were disconnected from each other, and from the rest of the guitar wiring when you checked them. If they were still wired together (and if the tone cap was still wired to the tone pot(s)), you may not get true readings. I don't know what a "Robert Cray" Strat has for a switch, but assuming it's a std Fender "5-way", this link gives some explanation of how it works, and should clarify how to test it: www.alloutput.com/Wiring/5way.html |

|

|

|

Post by sumgai on Aug 13, 2009 20:29:59 GMT -5

newey, A shielded cable entering into a cavity will not help protect the exposed terminals of the jack sitting within that cavity. Any radiation (that's strong enough) will still be able to enter and "infect" the hot terminal of the jack - said radiation is still going to go right through all that wood, whereas the shielded cable is able to protect the inner core wire for only as far as the braided shield is not stripped back (for soldering purposes). Tom, The jack cavity is usually just about big enough to allow the guitar cord's plug to enter and "snap" fully into position. That small deflection of the "hot" contact can easily touch the wooden wall behind it, if the cavity is tight (or if the jack mounting plate is slightly offset from its intended position). Of course, this means that any shielding will just ground the hot signal as soon as the plug is inserted, which will make grown men cry. The usual solution is to put a small piece of electrician's tape over the affected area. In time, the tape may come loose, but for the most part, it's a good fix. And it beats using some kinda hokey router/drill bit kludge to hog out more wood.....  HTH sumgai |

|

tom

Meter Reader 1st Class

Posts: 51

Likes: 0

|

Post by tom on Aug 13, 2009 21:22:45 GMT -5

D2o wrote:Thanks, D2o. I'll check it out. Newey wrote:That definitely entered my mind ! and. . .I hadn't stripped the wires on the Jb Jr. yet, so that's why I tested the circuit board. And yes, the pots, capacitor, and the 5 way switch (looks std) ARE still wired together just as they were originally. I haven't desoldered anything because I wasn't exactly sure what the final setup would be. sumgai wrote:It's funny. . .even with my "newbie" knowledge, I wondered about the effect of "exposed" leads and wires with regard to the noise/shielding issues. I didn't shield my buddy's jack cavity (does that sound disgusting ??!), but I did put some electrical tape around the jack wires as close as I could to the soldered connections to limit the "exposed" areas (not really knowing if that was overkill or not). I'm out of copper, but I could get some from a friend if I decide to shield the jack cavity. Would a little spray adhesive and then electrical tape be a good idea ?? Perhaps. . .shield the jack cavity with copper, spray with adhesive, then cover the (entire??) cavity with electrical tape    Just a novice thinking out loud. . .  Thoughts ??

|

|

|

|

Post by ashcatlt on Aug 13, 2009 21:56:00 GMT -5

I hadn't stripped the wires on the Jb Jr. yet, so that's why I tested the circuit board. And yes, the pots, capacitor, and the 5 way switch (looks std) ARE still wired together just as they were originally. I haven't desoldered anything because I wasn't exactly sure what the final setup would be. Were they still wired to the jack when you tested them? If not, then none of them can possibly effect the readings you got from any of the rest (your readings are correct). If so, then the volume pot may have affected one or both of the tone control readings, depending on the position of the switch. BTW, newey said something about "assuming these are in KOhm". Unfortunately .3 KOhm is way under spec. Luckily, we all know that the readings are actually in MOhm.  Just want to be sure that you understand that electrical tape alone will not make an effective shield. It doesn't conduct electricity, which is kind of the whole point of it. I think you've got that part, but... A good thick layer of acrylic paint over the copper could work too. |

|

|

|

Post by newey on Aug 13, 2009 21:58:28 GMT -5

Sumgai-

I take your point about the ends of the jack connections being yet exposed with the shielded cable. While that's technically true, I'm doubtful that, real world, it would make any discernible difference in noise levels.

Tom-

Electrical tape won't stop electromagnetic radiation any more than the wood of the guitar body will- much less so, I would think. We're shielding, not insulating. Any shield, to be effective, must be conductive and must be connected to ground. The idea is that the shield "captures" (a poor description, I admit) the stray electrical currents (noise) and conducts them to ground before they can "infect" (SG's word) our signal.

There's no need to tape over the entire jack cavity if you decide to shield it- the tip is our only concern. Here, the tape is being used as intended- to insulate the shielding from the tip. Whether spray adhesive would make the tape stick better, or just make a gummy mess, I don't know- never tried it.

BTW, I have noticed that electrical tape seems to adhere better on the aluminum foil I've used to shield guitars in the past than it does on the Stew-Mac conductive-glue copper tape I'm using nowadays. I'm having to rethink using electrical tape to keep hot connections off the shielding for that reason. But maybe I just need a better quality of electrical tape.

EDIT: Ninja'd by Ash again! He's right on your units, I missed the decimal and the fact that you were on the M range.

|

|

tom

Meter Reader 1st Class

Posts: 51

Likes: 0

|

Post by tom on Aug 13, 2009 22:21:18 GMT -5

No. Just the pots and the switch are still wired together - NO output jack. Yes, I understand. I just meant copper--->adhesive--->then tape over the areas that are close to the tip (and then. . .why not just do the whole cavity). RIP Les Paul. . .   |

|

tom

Meter Reader 1st Class

Posts: 51

Likes: 0

|

Post by tom on Aug 13, 2009 22:29:41 GMT -5

Sumgai- I take your point about the ends of the jack connections being yet exposed with the shielded cable. While that's technically true, I'm doubtful that, real world, it would make any discernible difference in noise levels. Tom- Electrical tape won't stop electromagnetic radiation any more than the wood of the guitar body will- much less so, I would think. We're shielding, not insulating. Any shield, to be effective, must be conductive and must be connected to ground. The idea is that the shield "captures" (a poor description, I admit) the stray electrical currents (noise) and conducts them to ground before they can "infect" (SG's word) our signal. There's no need to tape over the entire jack cavity if you decide to shield it- the tip is our only concern. Here, the tape is being used as intended- to insulate the shielding from the tip. Whether spray adhesive would make the tape stick better, or just make a gummy mess, I don't know- never tried it. BTW, I have noticed that electrical tape seems to adhere better on the aluminum foil I've used to shield guitars in the past than it does on the Stew-Mac conductive-glue copper tape I'm using nowadays. I'm having to rethink using electrical tape to keep hot connections off the shielding for that reason. But maybe I just need a better quality of electrical tape. EDIT: Ninja'd by Ash again! He's right on your units, I missed the decimal and the fact that you were on the M range. Newey, Yes, I understand. In the simplest terms, I just meant 1) shield it with copper, then 2) insulate it with the tape. (With the thought of. . .bigger strips of tape might equal better "staying power" than a few smaller pieces). Tom |

|

|

|

Post by newey on Aug 13, 2009 22:46:19 GMT -5

That should be fine. If you decide to use the adhesive as well, let me know how it goes, since I'm going to have to redo some electrical taping in my Strat cavity, around the area of the switches which are right up against the sides of the cavity in my 4Caster project. Other than the problem getting electrical tape to stay put on it, I'm a big fan of Stew-Mac's copper shielding tape with the conductive adhesive. Makes life so much easier!  |

|

|

|

Post by D2o on Aug 14, 2009 8:46:11 GMT -5

A good thick layer of acrylic paint over the copper could work too. I wonder if it would also be a good idea to put some on the outside of the tip of the jack as well? (sorry to beat this a bit ... but just to be clear, I do not mean apply paint on the inside of the tip where the cord makes contact) I have only shielded one jack cavity, and I think what I did was place the tape so that it was firmly adhered to the area behind the tip, but I had measured and cut it out so that there was a bit coming up over the top of the cavity, so that the actual jack plate became an integral part of holding the tape where it should be in the event that the tape's adhesiveness was ever lost. Holy run-on sentence, batman. D2o |

|

tom

Meter Reader 1st Class

Posts: 51

Likes: 0

|

Post by tom on Aug 14, 2009 19:37:59 GMT -5

Ok, guys. . . (sumgai. . .can you please insert a "beating the dead horse" smiley here !  ) No sooner said than done - here ya go, pardner! - - sumgai I have the Stew Mac shielded lead, an audio cable, and I bought an 18" piece of 22 G shielded phone wire from Home Depot as suggested by D2o. I also got some more Stew Mac adhesive copper from a friend, so I'm ready to shield the jack cavity and start putting this baby together. I figure what better way to decide on which wire to use than after a night of beer drinking (insert beer drinking smiley here  Done! Done!), so hopefully I will have some happy posts tomorrow !! ;D ;D ;D By the way, what is that small circular rout seen on the face of many strat bodies (especially the MIM ones) ??  Is it a jig for the router used for the routing process ? I'm pretty sure it serves no purpose, but I want to make sure. My body has one like the middle one shown here. . .  I have a neat idea to put a 2009 penny in it (the "cornerstone" of my build, if you would. . .). Funny, last night I wanted to see how it sized up with the ol' Lincoln, and as I was comparing the size, I dropped the penny and it fell right in. . .and I couldn't get it out !!  It fits perfectly (tightly). I was able to get it out - because it was a 1996 penny ! I'll put a little adhesive on the back first (probably unnecessary) to keep it from coming loose and rattling around (highly unlikely). Any problems with doing this ?? If not, NO STEALING MY IDEA WITH OUT PROPER REFERENCING !!    Ciao ! Tom |

|

|

|

Post by newey on Aug 14, 2009 19:53:13 GMT -5

Yes, you'll be 1 cent poorer. ;D

That's probably a good guess. The one in the neck pocket holds the guitar body during the finishing process (and is thus unpainted). So those must function in the routing process. Commercially, these are turned out on a CNC machine and I suspect the holes are registration points for the CNC process.

|

|

tom

Meter Reader 1st Class

Posts: 51

Likes: 0

|

Post by tom on Aug 14, 2009 20:02:09 GMT -5

Not unless I get rid of the guitar !!! ;D

Tom

|

|

|

|

Post by newey on Aug 14, 2009 21:33:39 GMT -5

Well, but you haven't accounted for the economic theory of "opportunity cost". It'll probably take you 15 minutes of your time to loosen the strings, remove the guard, and retrieve the penny. Is your time worth more than 4 cents an hour?   You could have used that same 15 minutes to do something more productive, something that would generate > .04/hr. The difference between that amount and one penny is your opportunity cost of retrieving the penny. ;D ;D Of course, if you were switching pickups and had the guard off anyway . . .But, then again, new pickups cost money . . .Oh, nevermind!  |

|

|

|

Post by sydsbluesky on Aug 14, 2009 22:05:22 GMT -5

Just put a spaghetti strainer in front of the amp whenever you play. It'll pass eventually.

|

|

|

|

Post by sumgai on Aug 15, 2009 1:48:43 GMT -5

Just put a spaghetti strainer in front of the amp whenever you play. It'll pass eventually. D@mmit Jesse, now I've gotta go give the cat the last few sprigs of catnip, in order to calm him down and convince him that I wasn't really laughing at him!  And we were saving that prime stuff for a really special occasion.  Kee-rist, kid, I don't know why you keep asking for it, but as long as you do keep it up, I (and others, no doubt) are just gonna keep +1'ing you until you cotton to how things are run aroond here. ;D sumgai |

|

tom

Meter Reader 1st Class

Posts: 51

Likes: 0

|

Post by tom on Aug 15, 2009 4:24:19 GMT -5

No, no, no. . . The way I see it, I'll just add an extra 5 cents to the selling price. I'm far from an economics guru, but that's a 20% return on my penny (minus installation charges. . .a labor of love, of course !). ;D What the F am I still doing up ??    Ive got work to do tomorrow !!   |

|

tom

Meter Reader 1st Class

Posts: 51

Likes: 0

|

Post by tom on Aug 23, 2009 22:56:17 GMT -5

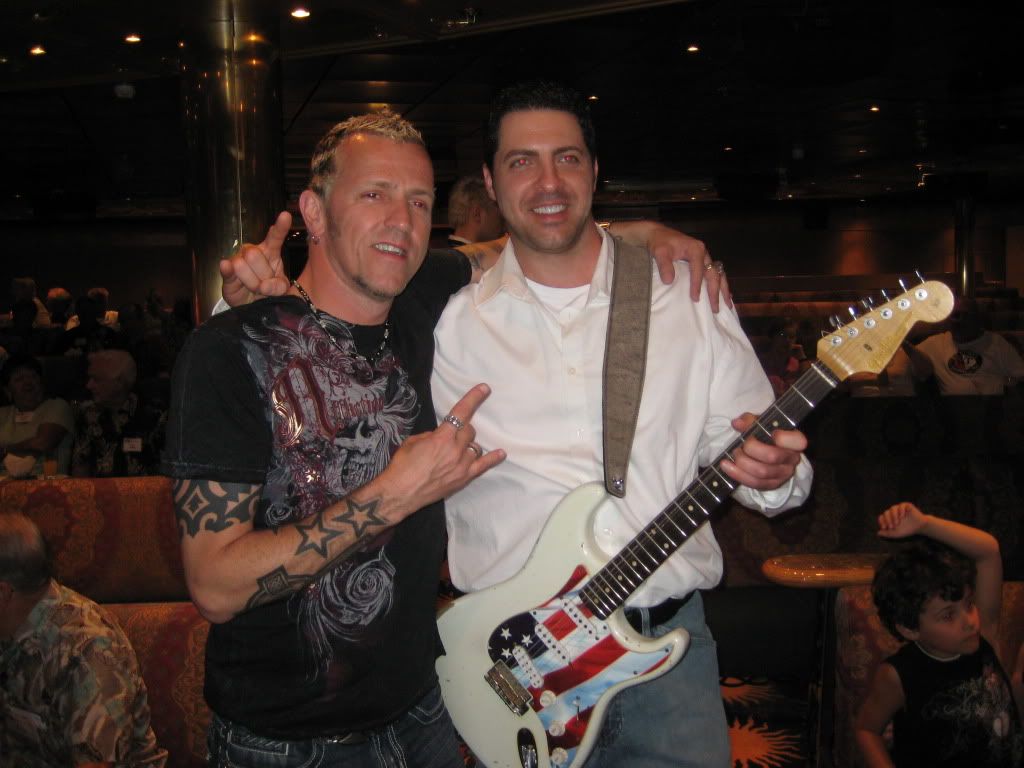

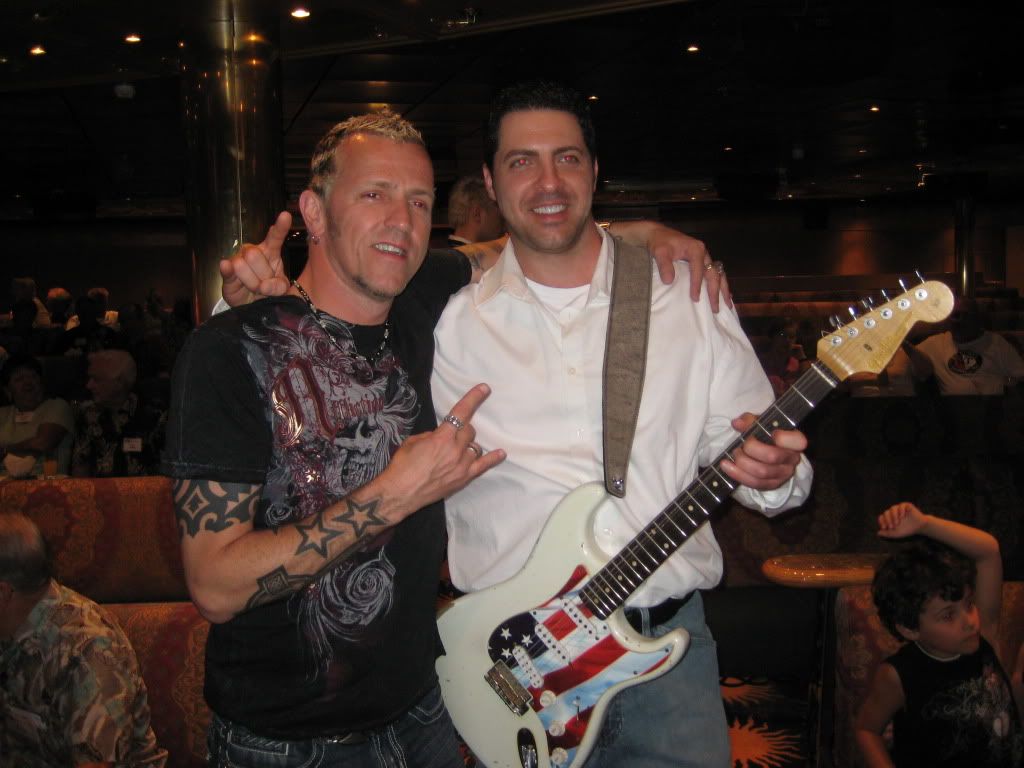

Hey everybody ! Did you think I was just going to get the info that I needed and then disappear ??   I had to make you sweat it out a little. . .  I finished it last Sunday. . .but I haven't gotten the chance to post because I couldn't stop playing it !! ;D ;D ;D For the last week, I have been uploading pics. . .it's taken me longer to do that than it did to put this thing together !!  I decided to document the entire step by step process and I posted some comments along the way. Maybe someone will find it useful in the future. . .  Thank you all once again for sharing your knowledge - it's much appreciated !! If you want see all 50 pics, here ya go. . . s968.photobucket.com/albums/ae169/bucketpics2009/Hoey%20Project/Here's the inspiration and the final product !   Rock on ! Tom |

|

|

|

Post by sumgai on Aug 23, 2009 23:29:30 GMT -5

Tom,

Good Job!! A mighty big +1 for ya!

sumgai

|

|

)

)

)

)

(However, while I do twist the pair of 20 or 22 ga. wires together, that's just to make it easier to feed them through the hole between the cavities, not for any hum-reduction effect.)

(However, while I do twist the pair of 20 or 22 ga. wires together, that's just to make it easier to feed them through the hole between the cavities, not for any hum-reduction effect.)

Done!), so hopefully I will have some happy posts tomorrow !! ;D ;D ;D

Done!), so hopefully I will have some happy posts tomorrow !! ;D ;D ;D