tom

Meter Reader 1st Class

Posts: 51

Likes: 0

|

Post by tom on Aug 25, 2009 9:03:30 GMT -5

Thanks, sumgai ! ;D As good as it plays and sounds, my perfectionism isn't satisfied. . .yet !  It still needs a little tweaking, but it has me a little confused.  I initially strung it up with 10's - Gary said he likes to use 10's and tune down a half step - so for completeness sake, that was my plan  . The neck was pretty straight and I was told by the guy who reliced it for me that he had played it and it sounded/felt great, so I assumed it was pretty close to where it needed to be. I set the saddle positions and the claw/spring tension in the "ballpark" of where I am used to, but after stringing up, every note on the fretboard was bottomed out and there was really no relief in the neck. I noticed that when I took the neck off to make the truss rod adjustment, it was at the "limit" of turning the screw counter clockwise to give more relief. I restrung and tweaked, and during the repeated process, both a B and two E strings broke when detuning them to make adjustments. (That's why I ended up with the 9's - ran out of 10's !) Since I can't get any more relief from the neck, I compensated as much as I could with saddle heights. However, they are as high as I have ever had/seen them. . .and there is still a little buzz in the upper register. Some of the set screws are at their limits as well. And the high E set screws appear much shorter than the rest. Here's one pic I have:  The nut height/slotting looks ok, although I have not taken any measurments. Unfortunately I have to run before I complete my post. . .but any suggestions ??  I may just stop off at a local custom builder/luthier and get his opinion. . .we'll see. Tom |

|

|

|

Post by D2o on Aug 25, 2009 9:48:28 GMT -5

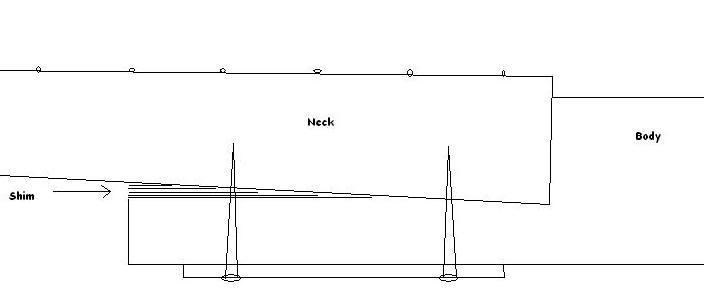

Hi Tom, Nice guitar, man! Did he take the neck off while he was relicing it? If so, did he misplace any little bit of material that may have served as a shim? Did you misplace any little bit of material that may have served as a shim? This has happened to me on occasion ... you remove a neck and, mysteriously, it's just not the same when you put the neck back on ... for whatever reason. Sometimes this happens even when I find a bit of shim material already in there, and replace it as near to where it was as I can. If that is the case, it may just need a little tweaking - I have used a shim in such circumstances (assuming I am correctly interpreting your post). In your case, the shim would be near the headstock end of the neck pocket, so as to "raise" the headstock, relative to the body, which would then allow you to have a little more room to play with, so you can lower the saddle heights and hopefully be able to back off with the set screws and still have proper intonation with the action you want. You can use wood, business cards, or a ramp made up of gradually decreasing pieces of paper piled on top of each other (piled/stacked, not a folded piece of paper - see below). In terms of relief, when using a straightedge what gap are you hoping for at the 7th or 8th fret? Cheers, D2o  |

|

|

|

Post by sumgai on Aug 25, 2009 13:07:26 GMT -5

Tom, My initial impression? You don't have enough string tension on the neck. Put on some 12's for a few days, tuned all the way up to concert pitch. See if that "convinces" the neck to assume the correct curvature..... If that seems to help, then you can go back to 10's, and see what happens, again after a few days. If the neck moves back to a "too straight" form (what you have now), then it's time to see your friendly local neighborhood luthier. But I suspect that once it's been pulled up by the higher string tension, that it will tend to stay there. Keep in mind that wood never reacts instantly. Sometimes it takes hours, or even days, for wood to fully settle into its new position, under some new infuence such as I'm suggesting. There are many factors that control this time frame, which is why most wood butchers just go with "at least a couple of days", and leave it at that. BTW, much as D2o and I are usually in agreement, I have to say this - don't worry about shimming until you get the neck's curvature set correctly. All the shimming in the world won't correct for a too-straight (or too-bent-upwards) neck. He shows you how to position the shim correctly in order to get the bridge saddles back down from their maximum height, but a neck that "frets out" all over the place is not a neck with a height problem. (Sorry, D2o.  ) HTH sumgai |

|

|

|

Post by D2o on Aug 25, 2009 13:23:59 GMT -5

BTW, much as D2o and I are usually in agreement, I have to say this - don't worry about shimming until you get the neck's curvature set correctly. All the shimming in the world won't correct for a too-straight (or too-bent-upwards) neck. He shows you how to position the shim correctly in order to get the bridge saddles back down from their maximum height, but a neck that "frets out" all over the place is not a neck with a height problem. (Sorry, D2o.  ) That's okay, sg - that's why I ended the post inquiring about the desired relief. D2o |

|

tom

Meter Reader 1st Class

Posts: 51

Likes: 0

|

Post by tom on Aug 25, 2009 15:36:40 GMT -5

Ahhhh. . . .dammit. . .I wanted to get back to my post before anyone responded.  D2o D2o. . .Just to clarify a few things. . . The neck was never bolted onto MY body until I did it for the first time. IOW, the guy that reliced the neck for me only ever had the neck and tuners (he ordered it directly from All Parts). He said he would rather drill the holes for the tuners himself to make sure everything checks out before he sent the neck to me after he reliced it. I would have rather done the drilling myself, but I had no problem with him installing the Sperzels. After he is finished relicing any of his necks, he likes to try them out to make sure there are no problems. So I guess he just bolts them on to a compatible body to make sure everything is ok. Sorry you had to go through the shimming explanation!   sumgai sumgai. . .you then answered what would have been my next question. I thought maybe letting the neck "baste" under the constant string tension (and several thousand string bends for the last week!   ), would have enabled the neck to gain a little relief (and me, too !). But it hasn't - albeit with 9's on it. I'm just curious as to why the neck has very little to no relief even with full string tension and and the truss rod screw at it's most counter clockwise position. I wanted to make sure there were no issues with regard to the All Parts neck dimensions vs. the Road Worn neck pocket dimensions. . .or some other factor such as the bridge, saddles, etc. I even had the claw screws in pretty far (for a few days) so that the bridge was flush with the body (hoping to get some relief similar to what you explained). So, have you had success with the process of using 12's, etc., that you mentioned ?? Tom [glow=red,2,300]EDIT:[/glow] By the way, if you were to pull this guitar off the wall and start playing it, you would probably only notice some minor fret buzzing. It plays and sounds great and the intonation is perfect at the 12th fret. But I'm just concerned that it's not as good as it should be if the starting point is a combo of no relief in the neck, a maxed out truss rod adjustment, and super high bridge saddles. No what I mean, Vern ??  |

|

|

|

Post by D2o on Aug 25, 2009 16:43:05 GMT -5

D2o. . .Sorry you had to go through the shimming explanation!   I actually completely missed that the "it" that was being reliced was the NECK ... especially having viewed the photo of the inspiration for the project, where the upper body looked reliced. Anyway, no sweat Tom ... the picture was easily modified for some other use - I don't know WHAT that use might be, but I'm sure kyle is in my head will think of something. Cheers, D2o  |

|

|

|

Post by ChrisK on Aug 25, 2009 17:53:21 GMT -5

If the highest frets (those located over the neck pocket) have the clearance issue, no amount of seasoning/tension, truss rod adjustment, or any such measures will have any effect whatsoever.

It's a simple mechanical engineering problem. If the bridge saddles need to be too high to effect higher fret clearance on these frets, only the saddle height relative to the plane of the frets at said high fret location will effect the proper relief. Bodies and neck heels are not adjustable in co-planarity aside from shimming or pocket pitch.

As D2o indicates, the neck must first be shimmed to effect the desired saddle height relative to the plane of the neck at said high frets. Once this is done (and it must be done first), then the adjustment of the truss rod will be effective. To effect this, I use a capo to ensure that all strings are pressed against the highest possible fret just off of the body.

My approach has always been to effect the desired saddle height first via shimming if necessary. Then (and only then) I adjust the the truss rod, which only has effect on the frets that are not directly over the body, to increasing effect as one goes down the neck.

I've seen too many necks ruined through wood compression from truss rod abuse. I've bought too many guitars from GC that were on fire sale from the absolute lack of understanding on the part of the sales noobs/jubblies on how to set up a guitar.

|

|

tom

Meter Reader 1st Class

Posts: 51

Likes: 0

|

Post by tom on Aug 25, 2009 20:58:48 GMT -5

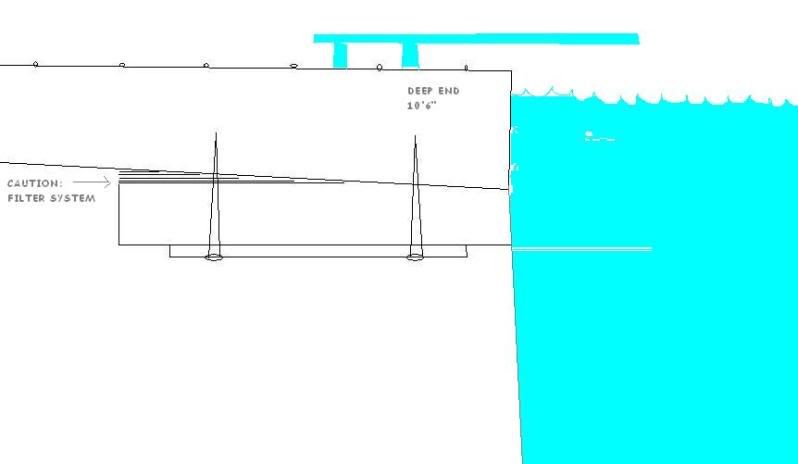

D2o said:Yes. . .you can "sorta" see the "minor" relicing in this pic . . .  ;D  (The pool looks quite refreshing, by the way !) s968.photobucket.com/albums/ae169/bucketpics2009/Hoey%20Project/?action=view¤t=IMG_0887.jpgChrisK. . .you reply is somewhat concerning. . . I'd like to think that in a way, many years of scientific coursework coupled with 20+ years of construction, carpentry, electrical, plumbing, and tile work, etc., . . .topped off with 10+ years of surgery. . .has contributed to a certain level of "intuitiveness" when it comes to anticipating/solving problems. I think that's the reason why I made this inquiry. I might not be an "expert" in a particular area and/or know what is causing the problem, but I understand that there "IS" a problem. And then I'm not satisfied until I elicit enough "expert" opinions and find a solution that also "makes sense" to me ;D ;D ;D. You said: So what exactly do you think is the cause   . The neck (truss rod) ?? Shouldn't any neck/body combo that is "compatible" work together without any problems ? That's why I stated: To me, if 3 "adjustable" factors combine to contribute to a desired result, something is rotten in Denmark if all 3 are at the limits of their adjustment "range". I'm really going to have to mull this one over for a while and more opinions are certainly welcome !    Tom

|

|

|

|

Post by ChrisK on Aug 25, 2009 21:58:08 GMT -5

I reiterate: " If the highest frets (those located over the neck pocket) have the clearance issue, no amount of seasoning/tension, truss rod adjustment, or any such measures will have any effect whatsoever." Do the highest frets on the neck have the problem? If so, shimming (angle modification) of the neck heel is required first. What is the heel thickness of the neck (from the back that fits into the pocket to the top of the fretboard)? What is the heel pocket depth? Is the bottom of the neck pocket coplanar (parallel) with the body top? Does the neck pocket have a tilt to it (such as for a TOM bridge)? Is the finish on the neck heel an even thin layer or does it get thicker closest to the neck heel bottom? All of these questions go to the coplanarity of the neck/body junction. USACG addresses the issue of coplanarity using "fall-away". www.usacustomguitars.com/neckfeatures.htmlIt would appear that the truss rod is not "maxed out", but is at its minimum adjustment. A single-acting truss rod has only one effect: to counter the bowing of the neck from string tension. Is the neck level when the strings are not under tension? Are the frets level? Here is some information on neck pockets and heels. Select "Will it Fit My Guitar". www.warmoth.com/Guitar/Necks/Strat_TotalVintage.aspx |

|

|

|

Post by newey on Aug 25, 2009 22:14:59 GMT -5

Tom said: The fact that you put the quotes around "compatible" leads me to believe that you don't even believe that yourself.  Interchangeable parts don't always interchange, especially wooden ones. Some luthier work is in order. I have never yet had a replacement neck that didn't need at least a bit of tweaking. ChrisK's post is only applicable if strings are fretting out on the highest frets. I don't see where we've really defined your problem in a specific way. You indicated that, until you raised the saddles to the max, every note was fretting out. Now, you have some buzzing at the limit of adjustments. Is the buzzing still across the board, so to speak? Can you play the uppermost frets without a buzz? And, was it the neck relic guy who took the truss rod to the limit of adjustment? If ChrisK's scenario is what you are experiencing, it's an issue at the interface between the neck and the pocket. Shimming may answer that, allowing you to get the saddle heights down a bit. How high does your fretboard sit off the body at the neck pocket? On most Strat type guitars, there is very little height there, the end of the fretboard sits pretty much flush with the pickguard there. |

|

|

|

Post by ashcatlt on Aug 26, 2009 11:11:36 GMT -5

You know, it took me a while to figure out exactly what was meant by the neck having been "reliced". Like, it had been liced at some point, then was maybe deliced, and needed to be reliced. But, shouldn't that be reloused?

Then I figured out that it's another instance of verbing a noun which is not meant to be verbed. Much like the noun verb.

There has recently been some debate (a noun which is perfectly happy to be verbed) re: the proper way to conjugate the verb form of the abreviation of the word microphone. Most people seem to spell it mic, miced, micing. These look to me like the kind of the thing farm cats do. It's a little strange, since one would never say "I microphoned my cab..."

Anyway, the point I'm trying to make is that this discussion has firmly left the territory of Electronics and Wiring.

|

|

|

|

Post by D2o on Aug 26, 2009 11:25:53 GMT -5

Good one, Ash (you've been cracking me up lately) I admit that the lice were a lot easier to see on the white body. Anyway, the point I'm trying to make is that this discussion has firmly left the territory of Electronics and Wiring. ... but we can still come back for conjugate visits, right?  |

|

|

|

Post by ChrisK on Aug 26, 2009 12:22:26 GMT -5

Yeah, and it's getting way too verbose in a nounular kind of way.

|

|

|

|

Post by sumgai on Aug 26, 2009 12:36:22 GMT -5

Tom, Obviously Chris and I come at this from opposites sides, but it is the same coin, nonetheless. Choose your methodology, and carry it through all the way - don't skip back and forth between methods, even if it seems to "make sense" at the time. Trust me on this.  And since you asked, yes, I have indeed installed 12's or 13's as method of causing the neck to bow up a bit. Doesn't always work, but most of the time it does, and it's usually enough to "re-set" the neck to a new position that is then usable with 10's. The only thing lost with this method, if it doesn't work, is time...... HTH sumgai |

|

tom

Meter Reader 1st Class

Posts: 51

Likes: 0

|

Post by tom on Aug 26, 2009 12:38:53 GMT -5

|

|

|

|

Post by newey on Aug 26, 2009 14:03:08 GMT -5

Well, it started as your project, and we're still discussing your project, even though we're moved from the electronic aspects to setup.

I think it should stay here or we'll all get headaches . . .

|

|

tom

Meter Reader 1st Class

Posts: 51

Likes: 0

|

Post by tom on Aug 26, 2009 14:39:34 GMT -5

Now this post is all "flaming" and what not. . .  Feel free to close this topic and continue it in the Lutherie and Repair section if need be. Ok. . .so where do I begin. . .I guess I'll try post to post. . . sumgai. . .Your suggestion (restringing with 12s or 13s for a few days is currently swirling around in my head being considered. . . ChrisK. . .Generally yes to varying degress, some worse than others. I don't recall - I would have to check that again. 1 inch. . .IIRC. Yes. (see pic link at the bottom) No. It's pretty much even (a very thin finish). Yes, a bad choice of words (it's minimum position is "maxed out". Kinda like that nouny verb, verby noun thing !  I guess I was thinking, spatially, the truss rod adjustment should fall somewhere inbetween. . .NOT at either of the extremes. (To be completely rudimentary and inaccurate, somewhere close to 12 o'clock on the dial as opposed to the extreme limits of 9 o'clock or 3 o'clock). That just gave me another headache ! The neck was straight before I ever put it on and when there is no tension on the strings, yes (see pic link at the bottom). When I detuned for the first time to adjust the neck for more relief, that was when I noticed that turning the screw counterclockwise (again, the first time), that it only took maybe a 1/4 to 1/2 turn before it was already "loose", ie., at it's "limit"). I didn't assess whether the frets were level (didn't have a good straightedge). Newey. . .In my haste, I was searching for a good word. I just meant a "standard" replacement strat neck that is designed to fit a "standard" strat body should fit without having to make major adjustments to the heel of the neck or the neck pocket. Maybe I'm taking this too literally and there is sometimes more work involved, like you said. At this point, this is probably the most accurate assessment. Yes, that is my concern. . .that I am at the limits of the adjustments that I can make. Yes, minimal buzzing down low, but more on the upper part of the neck. No. It only took that 1/4-1/2 turn the first time I adjusted it. Some pics. . . s968.photobucket.com/albums/ae169/bucketpics2009/Misc/That was painful !! Tom |

|

|

|

Post by newey on Aug 26, 2009 16:01:30 GMT -5

Tom-

It's hard to tell much from the photos, but to my eyes the fretboard looks like it's sitting a tad high.

But my eyes aren't what they used to be, so let's let others weigh in.

Or, if you have a buddy with a regular Strat, a side-by-side comparison ought to tell the tale.

|

|

tom

Meter Reader 1st Class

Posts: 51

Likes: 0

|

Post by tom on Aug 26, 2009 20:45:10 GMT -5

Tom- It's hard to tell much from the photos, but to my eyes the fretboard looks like it's sitting a tad high. But my eyes aren't what they used to be, so let's let others weigh in. Or, if you have a buddy with a regular Strat, a side-by-side comparison ought to tell the tale. I don't have another strat handy. . .but mine appears to measure 5mm from the BODY to the BOTTOM of the fretboard all around (both sides and the end). It measures 8mm from the BODY to the TOP of the fretboard on the sides and 10mm from the BODY to the TOP of the fretboard at the center of the radius on the end of the neck. If the neck does sit "too high", does that mean sanding/planing of the neck heel or neck pocket might alleviate the problem ? I still can't wrap my brain around the fact that the truss rod (I would assume) would still be at it's "limit" (the only adjustment that could ever be made would be towards straightening the neck - you would never be able to provide more relief if you needed to. . .) Tom |

|

|

|

Post by ChrisK on Aug 26, 2009 21:15:20 GMT -5

If so, shimming (angle modification) of the neck heel is required first. Shimming (angle modification) of the neck heel is required first. Verify that your heel pocket and neck meet these exact specifications. "Here is some information on neck pockets and heels. Select "Will it Fit My Guitar"." www.warmoth.com/Guitar/Necks/Strat_TotalVintage.aspxIf the pocket and heel dimensions check out, and the saddle screws are at their extension limit, maybe the vibrato bridge is set too low to begin with (adjust those six mounting screws on the tremo'Leo). Also one can buy extended saddle screws I believe. |

|

|

|

Post by lpf3 on Aug 26, 2009 21:28:13 GMT -5

|

|

tom

Meter Reader 1st Class

Posts: 51

Likes: 0

|

Post by tom on Aug 26, 2009 22:42:54 GMT -5

SORRY !! This was a typo. . .should have read 5/8". I checked this out yesterday. Yes, all measurements are the same. . .  [glow=red,2,300]EXCEPT FOR ONE[/glow] [glow=red,2,300]EXCEPT FOR ONE[/glow]. It appears that my rosewood slab fretboard is thinner - by a factor of about one half). It measures about 3mm (as opposed to the 6.35mm pictured here).  My neck also does not have the fretboard "overhang" as pictured above. (You can see the end of my neck in the most recent link to my pics that I posted). I didn't know the bridge was adjustable other than loosening the middle 4 screws a bit to let it pivot on the outer 2. . .   Not sure what that means ! Time for bed. . . Tom |

|

|

|

Post by ChrisK on Aug 26, 2009 23:17:10 GMT -5

Since your fretboard measures about 10 mm from the body top surface to the middle of the fretboard, this is very close to spec. The tremo'Leo vibrato bridge does not pivot on the outer two screws, it pivots on the two screws farthest from the neck. It's a silly design (not an engineered design), superseded by the two screw vibrato bridges of many makes. The saddle height is the sum of the saddle height above the vibrato bridge and the height of the 6 mounting screws effecting bridge height above the body. If the outer two screws are screwed down tight, the vibrato does not function and it may have insufficient height. Occam's RazorCheck the simple things first; the light's usually better.  |

|

tom

Meter Reader 1st Class

Posts: 51

Likes: 0

|

Post by tom on Aug 27, 2009 8:12:56 GMT -5

I think I see what you're saying here in terms of pivoting on the two "farthest" from neck. At first thought, I would assume that all of the screws would be equidistant from the neck, but I guess that's only true in the grossest sense. I suppose a screw hole (or two !) placed a half of a millimeter or so further from the neck is enough to make a difference, mechanically speaking.

Also, correct me if I'm wrong (since I'm a newbie!). . .but I guess technically, the pivot point would be between the bridge plate and the guitar body and not the screws themselves, right ? Anyway. . .

It's funny you mention Occam's Razor. I will admit, the combo of being a "newbie" to a lot of these things and trying to get the time to evaluate all of the suggestions during busy work days/nights makes it a little difficult for me to keep my thoughts on the matter organized. Like you say, I usually check the simple things first. I just installed the bridge as recommended by Fender and everything else that I have read. The problem is that there is no real "endpoint" in terms of "tight" or how much torque, for example, should be applied to the bridge screws. What constitutes too tight ? What is too much movement (or play) in the bridge ? What height is too low or too high ? This is where the experience of others in the know comes in - that's why I'm here ! ;D ;D

I have checked those things, but I will recheck tonight when I get home and report back. To my recollection, the outer two screws aren't cranked down with Herculean force (comfortably snug) and the inner four are a bit looser - but I don't recall how much "play" is there.

Tom

PS I think one of the inherent difficulties with forums in general is that there is no dialogue, but rather a series of monologues from different people. And I think some things get lost in translation (ie, "why didn't you check this first, dummy ?!". . .I did - I just forgot to mention it or assumed you assumed I did ! ;D ;D ;D)

|

|

|

|

Post by ChrisK on Aug 27, 2009 8:55:40 GMT -5

The pivot points are the beveled edge of the mounting screw holes and the shanks of the screws (those farthest from the neck until all equally wear in). If the pivot point was between the bridge plate and the guitar body, the bridge screw pivot points would slide up and down the mounting screw shanks. Here's a link as to why Fender factory vibrato (tremo'Leo) bridges are generally junk. www.callahamguitars.com/bridges.htmThese screws are screwed into the body. Torque is meaningless. The vibrato bridge plate must be free to tilt at least downward (detune only) or the vibrato will not be functional. If the vibrato plate is flush against the body, it will not be able to up tune (raise frequencies) and will cause the bridge plate to move up and down the screw shanks as it is operated. Since the underside of the mounting screw heads are flat (perpendicular to the shank), a "happy medium" point must be found such that the pivot points are somewhat further down the shanks than directly under the screw heads. This is why the mounting screws must be backed out enough to prevent the pivot points from siding up and down the shanks. Also note that Callaham indicates that the vintage 6 screw vibrato (he thinks that it's a tremo'Leo also) is only usable in the detune mode. I tend to agree, and generally only use them in a blocked vibrato mode ( a "fixed" bridge with the built-in reverb springs). Remember, a Strat is really an inside-out semi-acoustic guitar. |

|

tom

Meter Reader 1st Class

Posts: 51

Likes: 0

|

Post by tom on Aug 27, 2009 15:10:44 GMT -5

That was a good explanation. . .thanks ChrisK !  Again, as the Fender Strat (more specifically, putting one together ) is new to me, after your first post this morning I was trying to envision what the bridge plate, mounting screws, and the rest of the tremolo components look like (and how they work). I stumbled upon the page that you have linked above. After your explanation, it makes sense to me that the pivot point isn't b/t the bridge plate and the body - I guess I was just envisioning the plate also "pivoting" just at the front edge where it is beveled upward (presumably to avoid making a huge trough in the body of your guitar !!  ). When I looked at the tremolo for the very first time, I thought to myself, (not criticizing, of course, b/c I don't know anything about this stuff), "How in the world do these mounting screws not just break right off with heavy dive bomb usage ?! How can this thing ever stay in tune with even mild tremolo work ?!" It's usually really important to me to find out how/why things work, but I really didn't explore the facets of how the tremolo actually works since I was just a little eager to get this thing together due to time constraints. Really interesting stuff, though !!   Along those same lines, I'm really not a huge tremolo player, so I was just putting it on because it was part of the "project" that I was building, if that makes sense  . The only guitar that I still have is an Ibanez Sabre 470fm with the Lo Pro Edge Floyd Rose (or whatever it is) and I rarely ever put the whammy bar in it. Looks like this. . .  In addition to using my left hand for vibrato, I also use my right hand very frequently on the free floating bridge (probably more than my left !). I have become so used to using it that way, that it's become part of my "style" and when I play a guitar that has a non-floating trem, it's very disturbing for me !! My intent was to make the guitar as "true" to Gary's as I could, try to raise the bridge off the body within reason to satisfy my RH vibrato fetish, and go from there !  Sorry for the diatribe !!  I will see what kind of "tweaking" I can do to the bridge when I get home. Tom |

|

tom

Meter Reader 1st Class

Posts: 51

Likes: 0

|

Post by tom on Aug 27, 2009 16:28:26 GMT -5

Ok. . .so I checked out the bridge. . . The screws are not that "tight" and there is certainly some "play" there, so in my estimation, I don't think that any further adjustments in terms of raising the bridge will remedy the buzzing problem. This is one of the first things I tried when initially setting it up. (I just backed them off as much as I thought I could (just now, too) and it still made no appreciable difference). So, I guess we're back to square one (or 5 !), ie., . . .  Tom |

|

|

|

Post by ChrisK on Aug 27, 2009 17:54:57 GMT -5

Good, as tremolo (Amplitude Modulation) is not an effect realizable in an electric guitar. It is usually found in an amplifier, often erroneously called vibrato by Fender.

Vibrato (Frequency Modulation) however, is an effect often found in electric guitars, but never in non-DSP based amplifiers.

What's the difference between a Bigsby vibrato, a Floyd Rose vibrato, a Floyd Rose tremolo, and a Fender tremolo?

None other then the manufacturer's perennial lack of understanding, they're all vibratos. They all do the same thing......

|

|

|

|

Post by lpf3 on Aug 27, 2009 18:25:09 GMT -5

Tom- I'm sorry, nothin to do with your project- just a little joke ( maybe not a good one but still just a joke ) about something I was a little surprised to see. Glad to see, but still surprised No assumptions have been made, I'm just sayin'- ya know. I'll get the heck out of the way now. ;D  -lpf3 |

|

tom

Meter Reader 1st Class

Posts: 51

Likes: 0

|

Post by tom on Aug 27, 2009 19:08:37 GMT -5

I'm still not sure what you mean   . . .what were you surprised at seeing ??  |

|